DC Compressor is a supplier specializing in the import and export of gas compression equipment systems and components. Its products and services cover the sales of Atlas Copco and Ingersoll Rand units, parts sales, after-sales maintenance and repair of air compressors, waste heat recovery retrofitting, and the installation of energy-saving compressed air pipelines. It is a comprehensive service provider and has extensive partnerships with customers in various industries including steel, chemical, automotive, medical, telecommunications, electronics, hardware, machinery manufacturing, new energy, food and beverage, furniture, and packaging.

Our company provides: oil-injected screw air compressors, oil-injected screw variable frequency air compressors, oil-free air compressors, oil-free variable frequency air compressors, oil-free low-pressure screw air compressors, oil-free centrifugal compressors, and mobile air compressors.

We provide users with comprehensive technical solutions for aerodynamic systems, including design, installation, commissioning, technical consultation, energy-saving retrofitting, operation and maintenance, inspection and testing. Our company can offer multiple sales channels and preferential prices based on your brand's air compressor requirements, along with complete product transportation and after-sales support, while reducing your procurement costs. With a rigorous quality control system and supply chain management, our products have earned a good reputation in the international market.

Business Scope:

Import and export agent, providing customers with comprehensive import and export agent services, including but not limited to procurement, customs declaration, inspection, logistics arrangement and after-sales service.

Supply chain management, by optimizing the supply chain process, helping customers reduce costs, improve efficiency and ensure timely delivery of goods.

Market expansion, using our global business network to help customers explore international markets and find potential partners.

Customized service, according to customer needs, provide customized trade solutions to meet the special requirements of different customers.

We have now established extensive partnerships with clients across various industries, including steel, chemical, automotive, medical, communications, electronics, hardware, machinery manufacturing, new energy, food and beverage, furniture, and packaging.

Compressed air is known as the 'fourth utility' in the industrial sector, and its quality and stability are directly related to production processes, product quality, and operational costs.

Designing the compressed air system as a complete process chain is a necessary condition for achieving production reliability, high product quality, and low operational costs.

From the powerful pulse of the air compressor, the 'heart' of the system, to the deep purification of the post-treatment equipment, the 'kidneys,' and then to the efficient delivery through the pipelines, the 'blood vessels,' every part is meticulously designed, together forming a strong and reliable foundation of power in modern industry.

In the modern industrial system, after-sales service for air compressors is no longer just a supporting role, but a strategic partner in safeguarding the customer's core productivity.

What we offer is no longer just wrenches and parts, but 'Reliability as a Service' based on deep professional knowledge, advanced diagnostic tools, and refined processes.

By establishing this full lifecycle partnership, we jointly ensure that the lifeblood of industry—compressed air systems—remains strong, pure, and uninterrupted, ultimately maximizing the customer's production efficiency.

For modern air compressor after-sales service, rapid vehicle response is the ultimate expression of precise management and a solemn commitment to the customer's production efficiency.

It is not just the speed on wheels, but also the speed of information flow, decision-making response, and resource allocation.

By building an efficient system that integrates intelligent scheduling, combat-ready equipment, and standardized operations, we ensure that at the moment customers need us most, professional engineers with complete equipment can arrive on time to restore the customer's "industrial lifeline" as quickly as possible, minimizing downtime losses. This is our professional interpretation of "24/7."

The installation quality of an air compressor system directly determines its operational efficiency, stability, service life, and maintenance costs.

Professional construction, installation, and commissioning go far beyond simply 'positioning and connecting pipes'; it is a systematic project that integrates civil, mechanical, electrical, and control technologies.

Strictly adhering to every standard from planning, positioning, and piping to commissioning is not only the cornerstone of stable equipment operation but also a prerequisite for achieving system energy efficiency, extending equipment life, and ensuring production safety. Meticulous installation is key to maximizing the value of compressed air, the 'lifeblood of industry.'

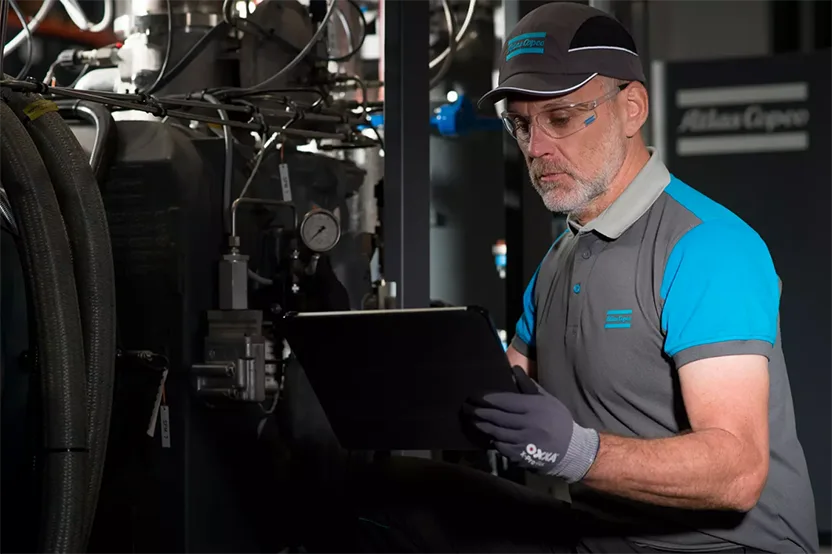

As a true maintenance partner, we understand your need for reliable, effective, and high-quality air solutions. Our goal is to maximize equipment availability and make the most of your resources with the lowest total operating costs.

All-weather, all-coverage

Relying on our team of factory-trained service technicians and our global logistics network, we ensure your compressed air is available 24/7.

Genuine Compressor Spare Parts

Our genuine compressor parts maintain excellent condition throughout the entire lifespan of your compressed air system. Always rely on genuine parts to ensure safe and high-quality operation.

Comprehensive Customer Care

Our technicians are all trained to closely monitor your equipment, identify any abnormalities, correct them as needed, and ensure your equipment operates smoothly every day. This is the starting point of our partnership.

Comprehensive, attentive, and thorough

We are meticulous and thorough, ensuring that every aspect related to safety is handled properly, paying attention to detail and maintaining professionalism. This is key to creating an exceptional service experience.

Atlas Copco service technicians are fully trained and highly capable; they are eager to listen to your needs and offer ideal solutions. They receive strong support from our global service organization at both the global and local levels.