Atlas Copco is renowned for designing and manufacturing durable Oil-Free Screw Air Compressor, and the ZR/ZT series screw compressors continue this tradition. They are the wise choice for industries with stringent requirements for high-quality oil-free air, offering high reliability, safety, and low energy costs. We are a professional air compressor manufacturer and supplier in China. Welcome to consult and purchase.

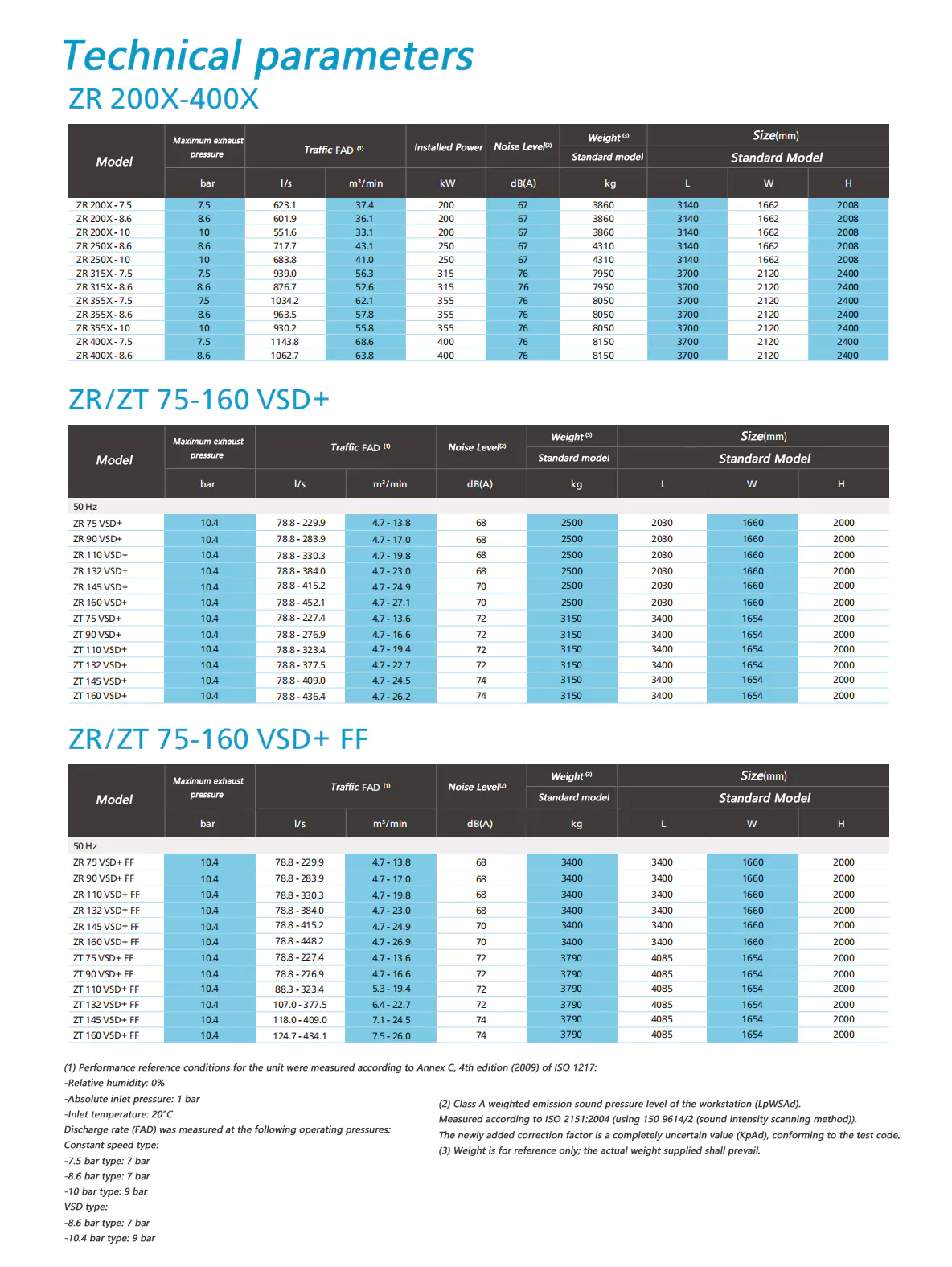

Core Parameters

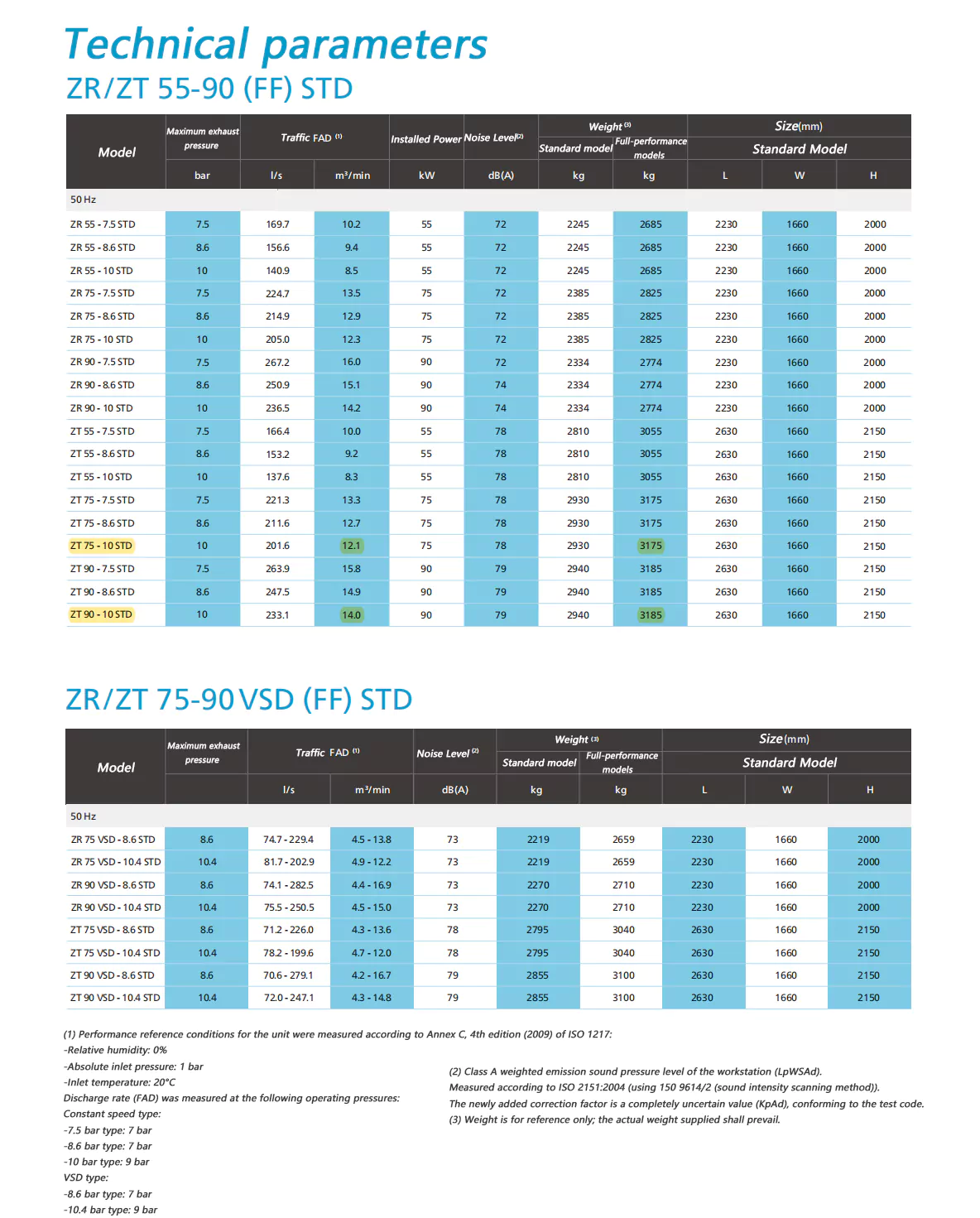

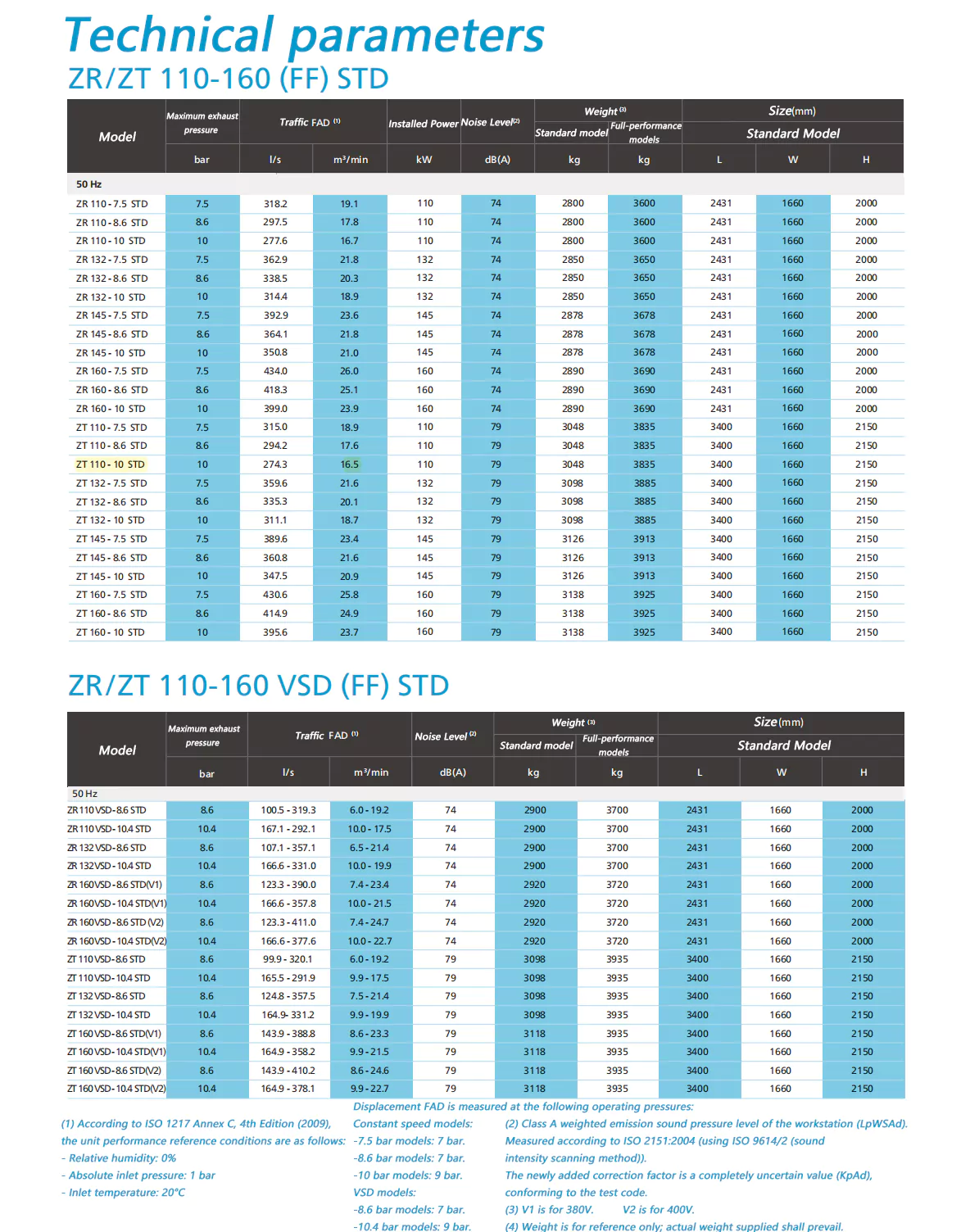

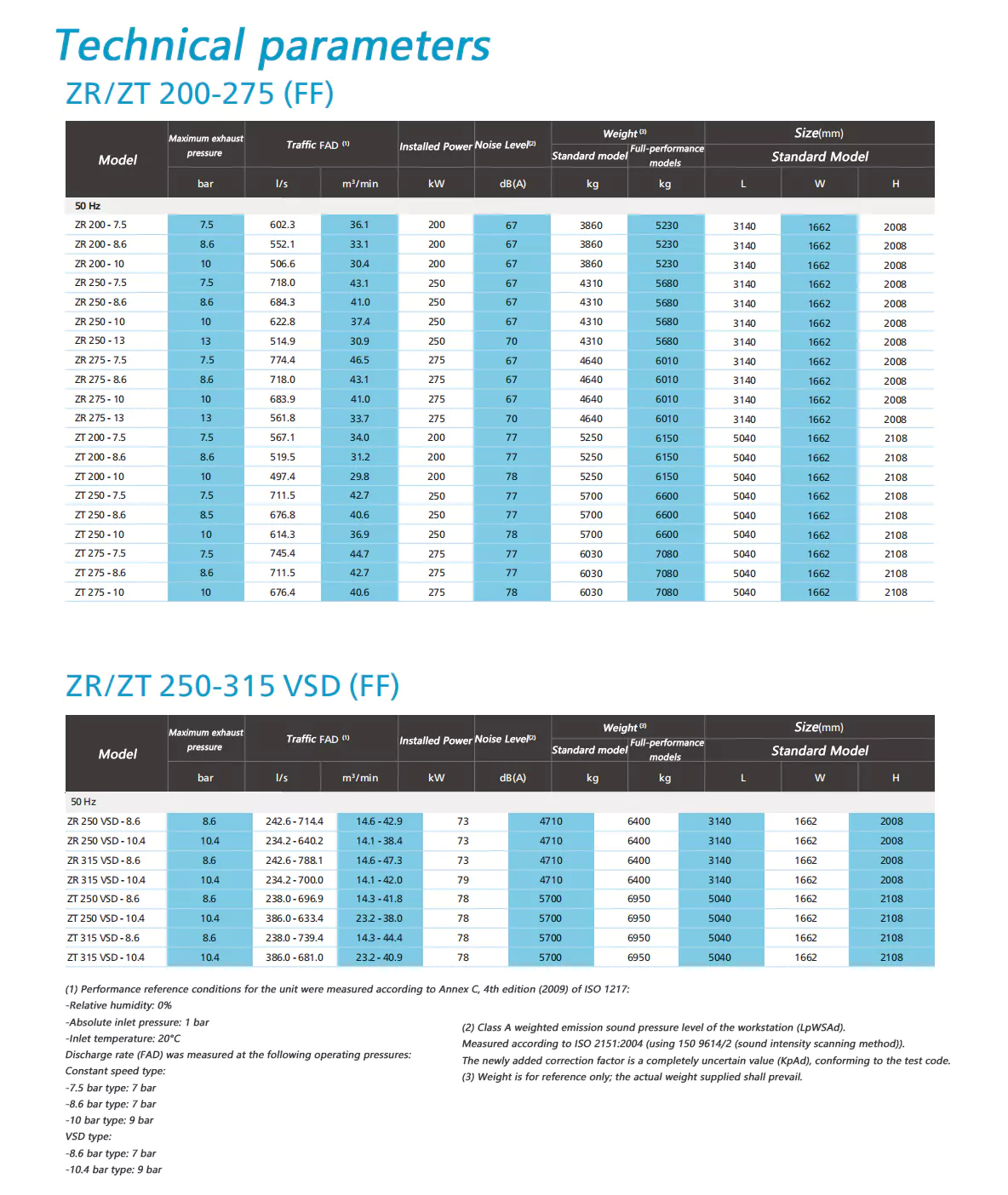

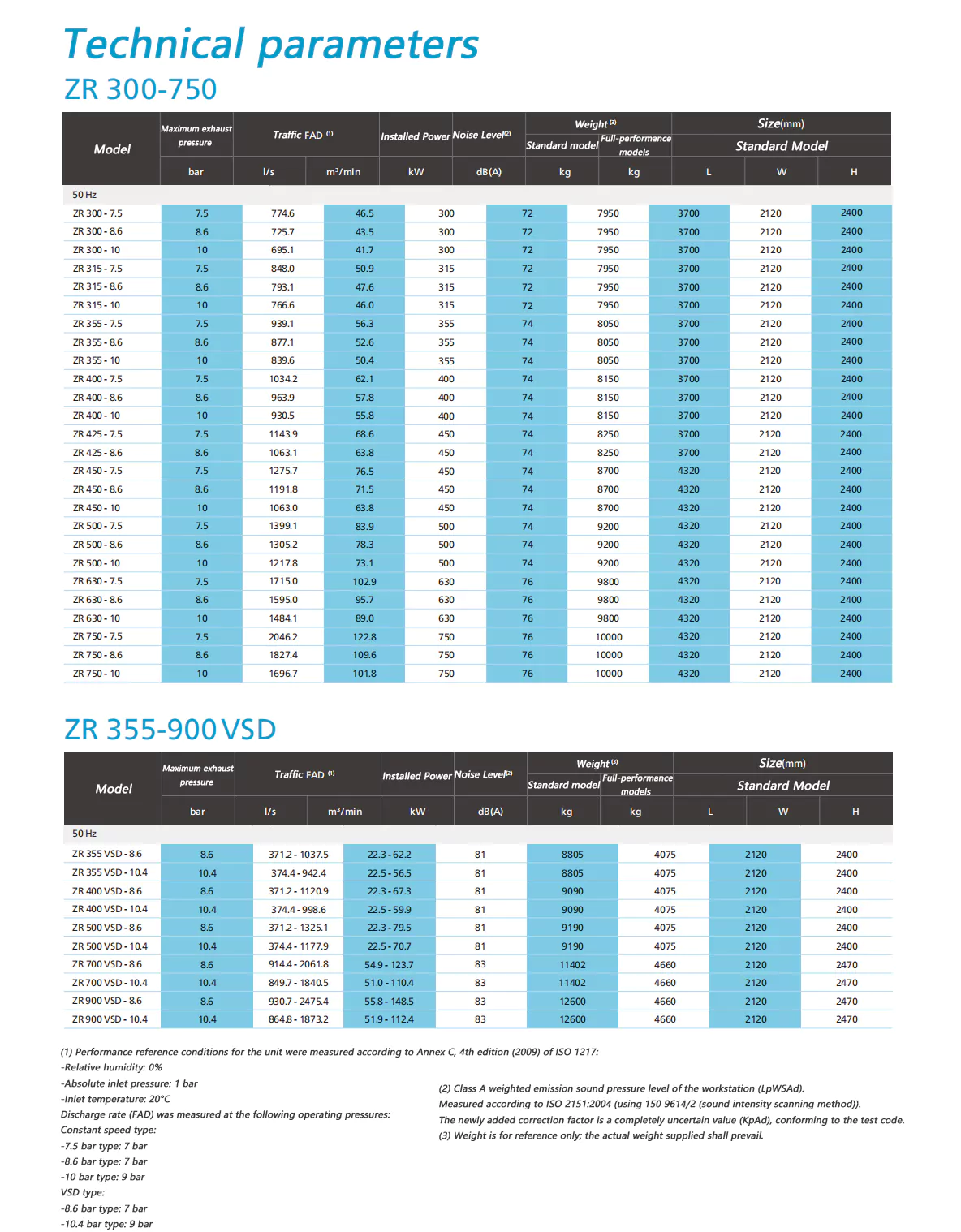

Displacement:4.2-148.5m³/min

Power:55-900kw

Industry Standard

Oil-free air is used in a wide range of industries where air quality is critical to final products and production processes, including food and beverage, pharmaceuticals, petrochemicals, semiconductors and electronics, medical, automotive painting, and textiles. In these demanding applications, even minute oil contamination can lead to costly downtime or product damage.

Pioneer in Oil-Free Air Technology

For the past 60 years, Atlas Copco has been dedicated to the research and development of Oil-Free Screw Air Compressor technology, launching numerous oil-free air compressors and blowers to provide customers with clean air. Through continuous research and development, Atlas Copco has once again achieved a new milestone, becoming the first air compressor manufacturer to successfully achieve CLASS 0 certification.

Eliminating Risks

To meet its customers' stringent requirements, Atlas Copco commissioned the renowned testing organization TÚV to test its oil-free compressors and blowers. TÚV employed rigorous testing methods, examining all possible forms of oil across a wide temperature and pressure range, and found no trace of oil in the output airflow.

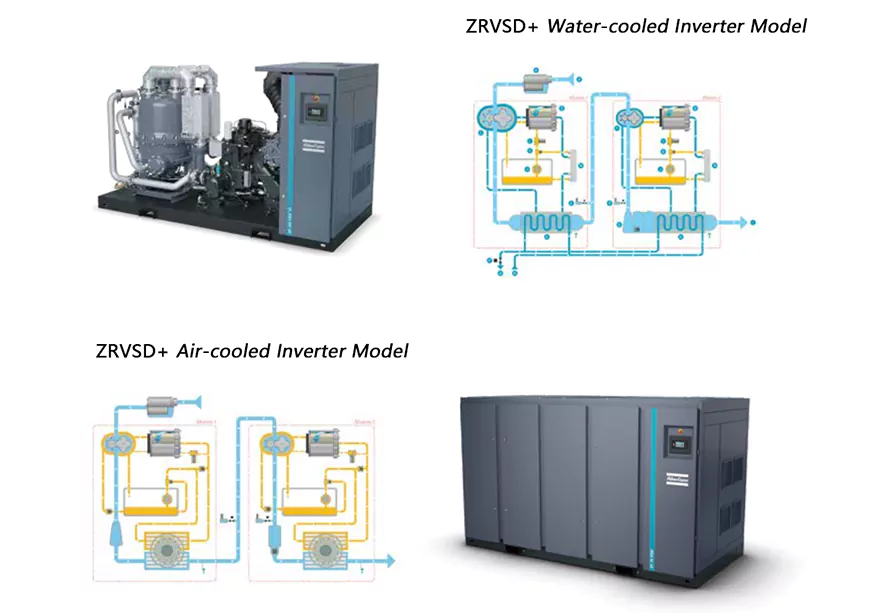

Mature Z oil-free screw technology, ZR water-cooled models

①Premium oil-free compressor head

• Unique Z-type seal design ensures clean, high-quality oil-free compressed air.

• Atlas Copco's premium rotor coating ensures high efficiency and durability.

• Cooling jacket.

②Advanced Elektronikon® Unit Controller

• Controls both the Oil-Free Screw Air Compressor and dryer simultaneously through an integrated control system.

• Provides overall system performance status monitoring via proactive maintenance instructions, fault alarms, and safety shutdown functions.

• Multiple display languages available.

• Specifically designed for connection to ES system horizontal control,

integrated with standard series communication protocols.

③Add/Unload Valve

• No external air supply required.

• Mechanically interlocked inlet and vent valves.

• Extremely low unloading power.

④High-efficiency cooler and water separator

• Corrosion-resistant stainless steel tube bundle.

• Highly reliable robotic welding; leak-free.

• Aluminum star-shaped fins for increased heat exchange area.

• Labyrinth-designed water separator effectively separates condensate from compressed air.

⑤High-efficiency motor + VSD

• TEFC IP55 motor prevents dust and chemical ingress.

• Continuous operation under harsh ambient temperature conditions.

• Direct energy savings of up to 35% with variable frequency drive (VSD) motor.

• Adjustable flow rate range from 30% to 100%.

The ZT air-cooled model boasts a comprehensive and outstanding design.

①Employs AGMA A5/DIN Grade 5 gears

• Long service life

• Low transmission loss, reducing noise and vibration.

②Premium Oil-Free Compressor Rotor

• Premium oil-free rotary screw compressor delivers high-quality air.

• Superior rotor coating and cooling jacket ensure overall compressor efficiency.

③Superior Rotor Bearings

• Maintain high stability under various load conditions.

• Easily adapt to load variations.

④High-efficiency air cooler

• Stainless steel precooler with heat sink.

• Superior heat exchange performance.

• Easy to clean.

• Low-noise, low-energy radial cooling fan.

⑤Integrated VSD

• Direct energy savings of up to 35% with the help of a variable frequency drive (VSD) motor.

• Significantly reduced unloading losses.

• No venting, preventing compressed air from being wasted into the atmosphere.

• Flow rate adjustment range of 30% to 100%.

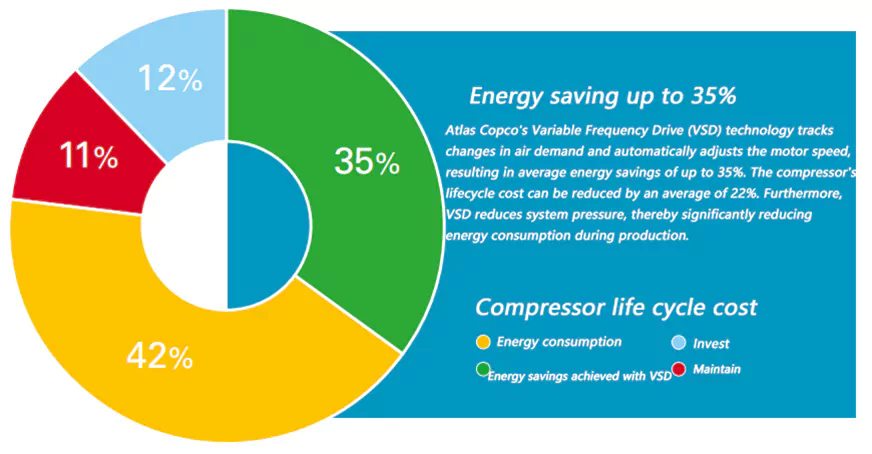

Variable Frequency Drive (VSD): Reducing Energy Costs

Energy consumption accounts for over 80% of the total lifecycle cost of a Oil-Free Screw Air Compressor. Furthermore, electricity used in compressed air production accounts for over 40% of a factory's total electricity costs. To reduce energy costs, Atlas Copco pioneered Variable Frequency Drive (VSD) technology in the compressed air industry. VSD not only saves significant amounts of energy but also protects the environment for future generations. Thanks to continuous investment in this technology, Atlas Copco is able to offer the widest range of integrated VSD compressors on the market.

The unique features of Atlas Copco integrated VSD

1. Elektronikon* simultaneously controls the compressor and integrated inverter, ensuring safe operation.

2. VSD offers flexible pressure selection from 4-10 bar, reducing electricity costs.

3. Custom-designed inverter and motor (with protected bearings) provide high efficiency across the entire speed range.

4. The motor is specifically designed for low-speed operation, fully considering the cooling requirements of both the motor and compressor at low speeds.

5. All Atlas Copco VSD compressors are certified and licensed. Compressor operation does not affect external equipment, and vice versa.

6. Reinforced mechanical components ensure that the operating speed range of key components is controlled below critical vibration levels.

7. The high-efficiency inverter built into the electrical control cabinet ensures stable compressor operation in ambient temperatures up to 50°C/122°F (standard operating temperature up to 40°C/104°F).

8. There is no "speed window" that increases energy consumption or affects net pressure stability; the compressor's gas flow rate adjustment range is as low as 75%.

9. Pipeline pressure fluctuations should be kept within 0.10 bar (1.5 psi).

Atlas Copco ZVSD+ Dual Permanent Magnet Inverter Drive

• Oil-Free Screw Air Compressor adopts a new generation of highly efficient compressor heads to improve compression efficiency.

• Each of the high-pressure and low-pressure compressor heads is equipped with an IP66 high-efficiency permanent magnet variable frequency motor (IE5), which adjusts the speed in real time according to changes in compressed air demand, saving energy and improving efficiency.

• Reliable oil-lubricated bearings.

• Atlas Copco's custom-designed frequency converter allows for high-flow-rate frequency adjustment between 20% and 100%.

• Compact design saves installation space.