Low-Pressure Oil-Free Screw Air Compressor series of Atlas is an oil-injected screw product developed for low-pressure applications. It can offer you more important things: more energy conservation, more compressed air, and a longer lifespan. Advanced compression components and many advanced functions ensure stable performance and excellent efficiency. We are a professional air compressor manufacturer and supplier in China. Welcome to consult and purchase.

Maintenance-free drive system

• Maintenance-free, fully enclosed, preventing dust and debris from entering

• Low-Pressure Oil-Free Screw Air Compressor is suitable for harsh environments

• High-efficiency gear drive, without the efficiency loss of couplings

• The maximum operating ambient temperature for the standard model is 46˚C, and for the high-temperature model, it is 55˚C

Ultra-efficient motor

• Motor efficiency class IE4

• Protection class IP55, insulation class F, temperature rise class B

• The non-drive end adopts grease-lubricated maintenance-free bearings

• Suitable for continuous operation in harsh environments

• Efficiently filter impurities in the oil to extend the service life of parts

•The oil filter is equipped with a bypass valve

Independent super-large designed oil cooler and aftercooler

•The low temperature at the rotor outlet ensures the long service life of the oil

•The built-in mechanical steam-water separator can remove nearly 100% of the condensate water

•The stress-relieving design eliminates thermal shock in the heat exchanger

•Remote control, alarm output, maintenance and servicing plans, and network diagnosis are all available

•Built-in Smartlink remote diagnosis maximizes the performance of the air compressor system and achieves energy conservation

•Diagnosis of multiple compressors (2,4 and 6 units in joint control are optional)

•Heavy-duty air intake filter

•Low-Pressure Oil-Free Screw Air Compressor can remove 99.9% of coarse particle dust, enhancing the protection of compressor components

• Extremely long service life

Atlas GL 37-75 features outstanding efficiency, excellent compressed air quality, low energy consumption under stable gas usage conditions, and intelligent characteristics that ensure efficiency and reliability. The Elektronikon" touch controller is adopted, featuring real-time remote diagnosis and optimization suggestions provided by SMARTLINK, as well as OPCUA for integration into production systems.

|

Compressor Model |

Work Pressure |

FAD*Flow |

Motor Power |

Noise |

Weight |

Export Size |

||

|

Bar(e) |

l/s |

m³/min |

kW |

hp |

dB(A) |

kg |

||

|

GL 37 |

4-5.5 |

139 |

8.33 |

37 |

50 |

68 |

1420 |

G212” |

|

GL45 |

4-5.5 |

175 |

10.5 |

45 |

60 |

68 |

1490 |

G212” |

|

GL55 |

4-5.5 |

242 |

14.5 |

55 |

75 |

69 |

1570 |

G212” |

|

GL75 |

4-5.5 |

290 |

17.4 |

75 |

100 |

69 |

1650 |

G212” |

|

Model |

Standard Model |

||

|

Long(mm) |

Wide(mm) |

High(mm) |

|

|

GL37/45/55/75 |

1,680 |

1,221 |

1,980 |

The performance parameters of the unit are measured in accordance with ISO1217, Annex C and 2009

Workstation sound pressure level test: LpWSA (ref 20 μPa) dB(A)(error: 3dB(A))

The noise level is measured in accordance with ISO2151 and ISO9614 standards

FAD is measured at the following working pressures: 5 bar for the 5.5 bar model

Reference operating conditions: Absolute intake pressure: 1 bar

Air intake temperature: 20°C

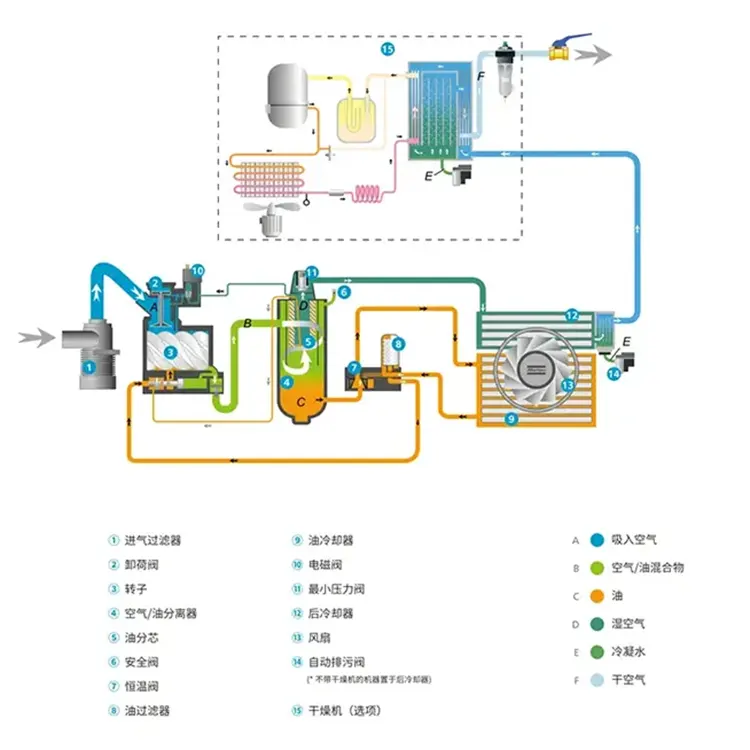

The main structure of Atlas GL 37-75 air compressor

1. Main unit section: It includes the intake valve, exhaust valve, transmission system, etc., which are used to achieve air intake, compression and exhaust.

2. Auxiliary systems: including the lubricating oil system, cooling water system, electrical control system, etc., are used to ensure the normal operation of the air compressor.

The working process of Atlas GL 37-75 air compressor

1. Startup stage: When the power button is pressed, the electronic control system will automatically start the lubrication system and cooling water system of the air compressor. At the same time, the intake valve opens and air enters the interior of the main unit.

2. Compression stage: As the screw rotor rotates, the air inside the main unit is subjected to the compression force, and the pressure gradually increases. At this point, the exhaust valve is closed to prevent the compressed gas from flowing back.

3. Exhaust stage: When the set pressure value is reached, the electronic control system will automatically activate the exhaust valve to discharge the compressed gas. Meanwhile, the intake valve is closed and the Low-Pressure Oil-Free Screw Air Compressor enters the state of waiting for the next start.

4. Shutdown stage: When it is necessary to stop the operation of the air compressor, press the shutdown button. The electronic control system will shut down the lubrication system and the cooling water system, and gradually close the intake valve and the exhaust valve. Finally, the air compressor stopped working completely.

Atlas GL 37-75 air compressor working flow chart