Atlas Copco offers you the professional Diesel-powered Mobile Air Compressor. This unit consists of two high-efficiency compressor components, Diesel engine, cooling, air/oil separation and control system, with high system reliability and wide application range of a single compressor. We are a professional air compressor manufacturer and supplier in China. Welcome to consult and purchase.

Standard Scope of Supply

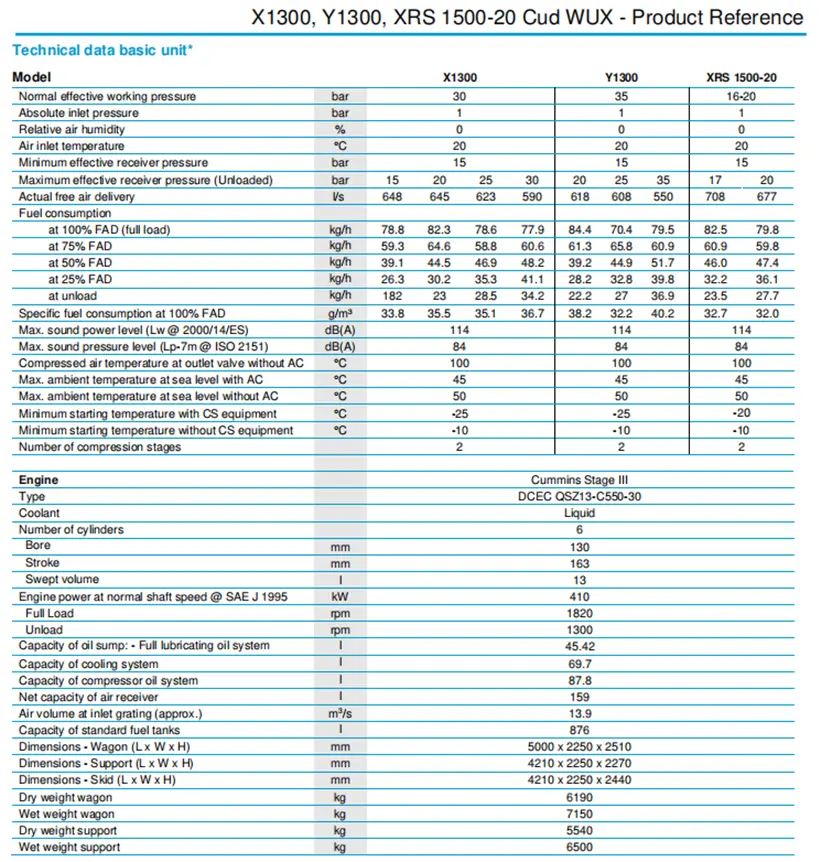

The Atlas Copco X1300, Y1300 and XRS 1500-20 are silenced, two-stage, oil-injected screw compressors, powered by liquidcooled, six-cylinder Cummins diesel engine.

The unit consist of two high efficient compressor elements, diesel engine, cooling, air/oil separation and control systems - all enclosed within a sound dampened power coated steel enclosure.

Special attention has been given to the overall product quality, user friendliness, ease of serviceability, and economical operation to ensure best in class cost of ownership

Available Models

|

X1300 |

Two Stage – 1250 cfm@435 psi – Cummins Diesel Engine |

|

Y1300 |

Two Stage – 1165 cfm@508 psi – Cummins Diesel Engine |

|

XRS |

1500-20 Two Stage – 1434 cfm@290 psi – Cummins Diesel Engine |

Features

• DrillAir™

• Oiltronix™ V2

• Additional 3% fuel savings

• New concept of oil separator vessel

• XPR

• Dynamic flow boost

Benefits

• 30% increase in drilling speed and cover wide range of application with one single compressor

• High system reliability, avoiding formation of water in the compressor oil system and an extended element lifetime

• No manual regulating valve or pressure regulating lines eliminates their associated freezing problems

• Save 1 hour for OSE change

• Offer extended range to cover more applications

• Offer 10% more flow during flushing and stem refil

Compressor Element

The quality of a compressor can be measured through the reliability, efficiency and durability of the compressor element used. Through decades of expertise in the design of compressor elements, the result is the production of most efficient and reliable compressors on the market.

Air/Oil Separator

Air and oil separation is achieved through a centrifugal oil separator combined with a filter element.

Designed for a higher maximum working pressure, the separator is equipped with a sealed high-pressure safety relief valve, minimum pressure valve, automatic blow-down valve, and pressure regulator.

Cooling System

The engine is provided with a liquid-cooler and intercooler and the compressor is provided with an oil cooler. The cooling system is suitably designed for continuous operation in ambient conditions up to 50°C, with all canopy doors closed.

Compressor Regulating System

Diesel-powered Mobile Air Compressor regulating system consist of air filters, an air receiver/oil separator, compressor element, an inlet valve assembly with inlet valve and a blow down valve; all controlled by an electronic regulating system.

The variable regulating system gives full control of compressor pressure and flow. It controls vessel pressure and outlet flow by measuring air pressure and air temperature at several points and controls the air inlet valve, engine speed and blow off valve corresponding the values measured.

Economic fuel consumption is assured by the fully automatic step-less speed regulator that adapts engine speed to air demand.

Discharge Outlets

Compressed air is available from 1 x G2.

Engine

Cummins Diesel Engine

The Diesel-powered Mobile Air Compressor is driven by a liquid-cooled, six-cylinder Cummins QSZ13-C550-30 diesel engine. The engine’s power is transmitted to the compressor element through a heavy-duty coupling.

Electrical System

The X1300, Y1300 and XRS 1500-20 are equipped with a 24-volt negative ground electrical system.

Instrumentation – XC4003

The XC4003 control panel is located on the front of the compressor canopy.

The intuitive Atlas Copco XC4003 controller is easy to operate with all functions conveniently at your fingertips. The controller also manages the engine ECU operating system, and a number of safety warnings and shut downs on various parameters (listed below).

XC4003 Controller Functionality:

• Main Screen

- Vessel Pressure

- Fuel level

- Running Hours

- RPM

- Air Flow CFM

• General Settings

- DPF Stationary Regeneration

- Engine Diagnostics

- Auto Start/Load/Stop

- Languages

- Units of Measure

• Measurements

- Fuel Consumption

- Engine Coolant Temperature

- Compressor Element Temperature

- Vessel Pressure

- Engine Load

- Engine Oil Pressure

- DPF Soot Load

- Fuel Temperature

- Battery Voltage

- Regulatory Pressure

- Loaded/Unloaded Hours

- Successful/Unsuccessful Starts

- Service Timers (2)

• Operational Controls

- Preset flow or operating pressure

• Service

- Data trending

- Project Backup

• Alarm

- Active Alarms

- Event Log History

- Alarm Log History

Safety Devices

The compressor is standard equipped with safety devices for the compressor and the engine. The unit will be completely turned off should:

- Engine oil temperature rise too high

- Engine oil pressure drop too low

- Outlet temperature of the compressed air goes outside a specified range.

- Low fuel level

The starter motor is also protected against overloading from operating for an excessive period or when the engine is running.

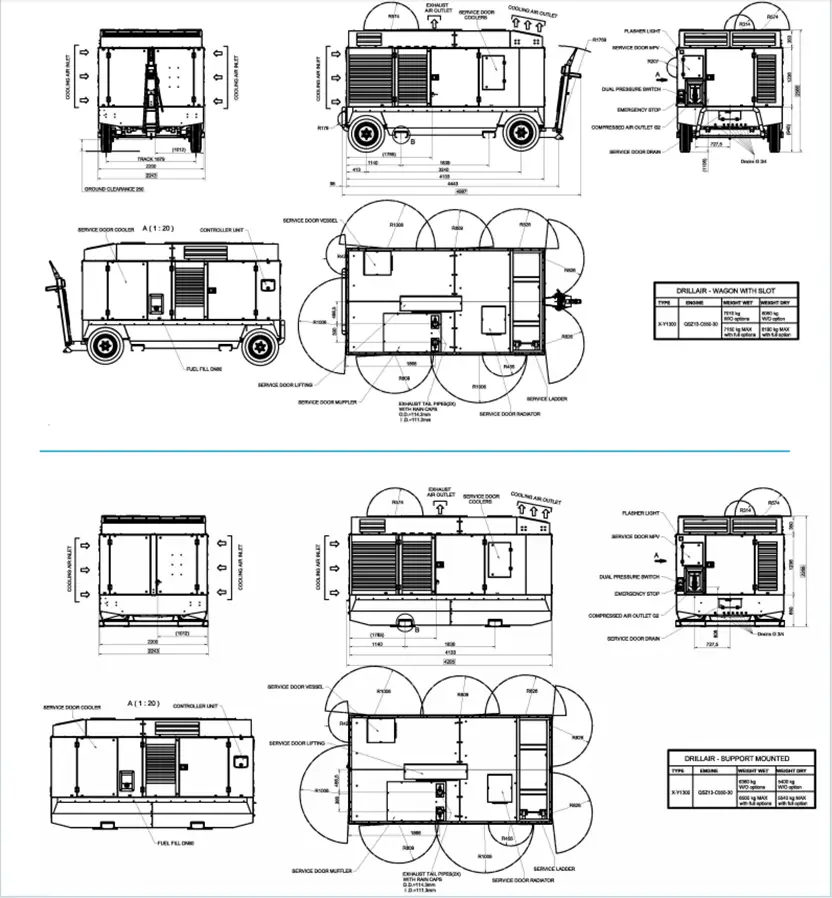

Bodywork

Diesel-powered Mobile Air Compressor is delivered as standard with a zinc coated steel canopy with powder coat paint finish providing excellent corrosion protection.

Wide doors provide complete service access to all components.

Manufacturing & Environmental Standards

The X1300, Y1300 and XRS 1500-20 are manufactured following stringent ISO 9001 regulations, and by a fully implemented Environmental

Management System fulfilling ISO 14001 requirements. Attention has been given to ensure minimum negative impact to the environment.

Supplied Documentation

The unit is delivered with the following documents and certificates:

- Spare parts list for compressor.

- Instruction manual for both compressor and engine.

- Machine test certificate.

- Vessel certificate.

Warranty Coverage

• Please refer to product presentation for warranty info.

• Extended Warranty Programs are available; please contact your local sales representative for more info.

* Note: Due to continuous improvements in the products, the technical specifications are subject to change without prior notice.