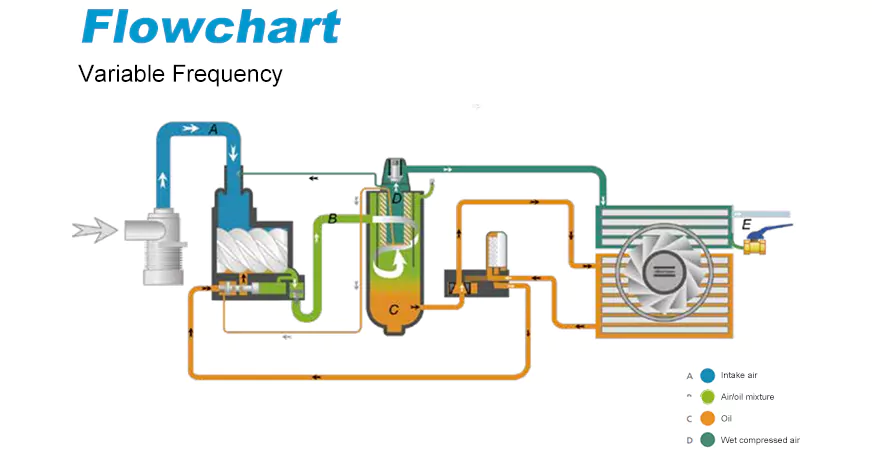

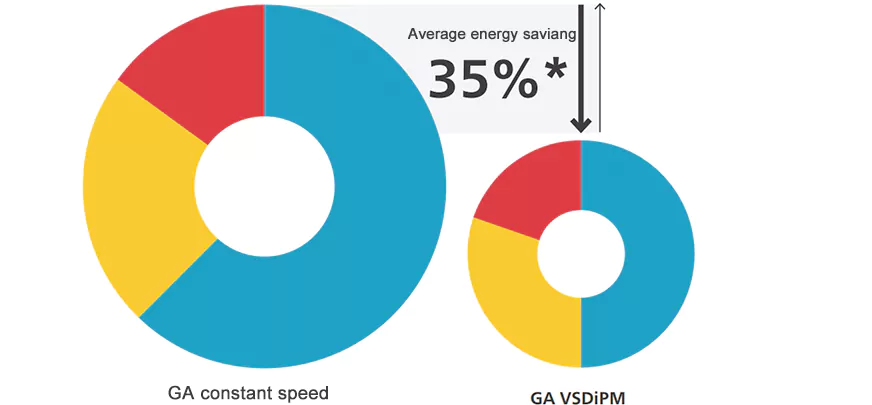

The VSD Variable Frequency Air Compressor of Atlas is specially designed for continuous operation. The drive system adopts an efficient permanent magnet motor, which can achieve excellent oil cooling effect. VSD technology can achieve energy savings of up to 35%, and its smaller footprint ensures installation flexibility.

High reliability

The VSD Variable Frequency Air Compressor is specifically designed for continuous operation.

It can operate reliably at temperatures up to 46 ° C/115 ° F.

Variable frequency starting can reduce the stress on key components and lower the starting current.

Standard equipped with a high-temperature thermostatic valve.

Low operating costs

VSD technology can achieve energy savings of up to 35%.

IE4 high-efficiency oil-cooled permanent magnet (PM) motor.

Advanced components convey more air with higher efficiency.

Easy to install and maintain

Floor-standing or tank-mounted installation versions are available for selection.

The smaller floor space ensures the flexibility of installation.

The main components, oil separator and filter are easy to maintain and operate.

We are a professional air compressor manufacturer and supplier in China. Welcome to consult and purchase.

1. High-efficiency drive system

The drive system adopts high-efficiency permanent magnet motors (IPM), which comply with the IE4 standard.

The reasonable and exquisite design can achieve excellent oil cooling effect.

IP54 protection.

2. W-shaped fin cooling system

The W-fin design ensures reliable operation under harsh conditions.

Axial flow fans can enhance the cooling performance.

3. Electrical cabinet

Advanced touchscreen controller.

The frequency converter, specially designed for air compressors, can provide self-regulating control in abnormal situations.

4. Durable oil filters/oil separators

The oil filter is equipped with an integrated bypass valve.

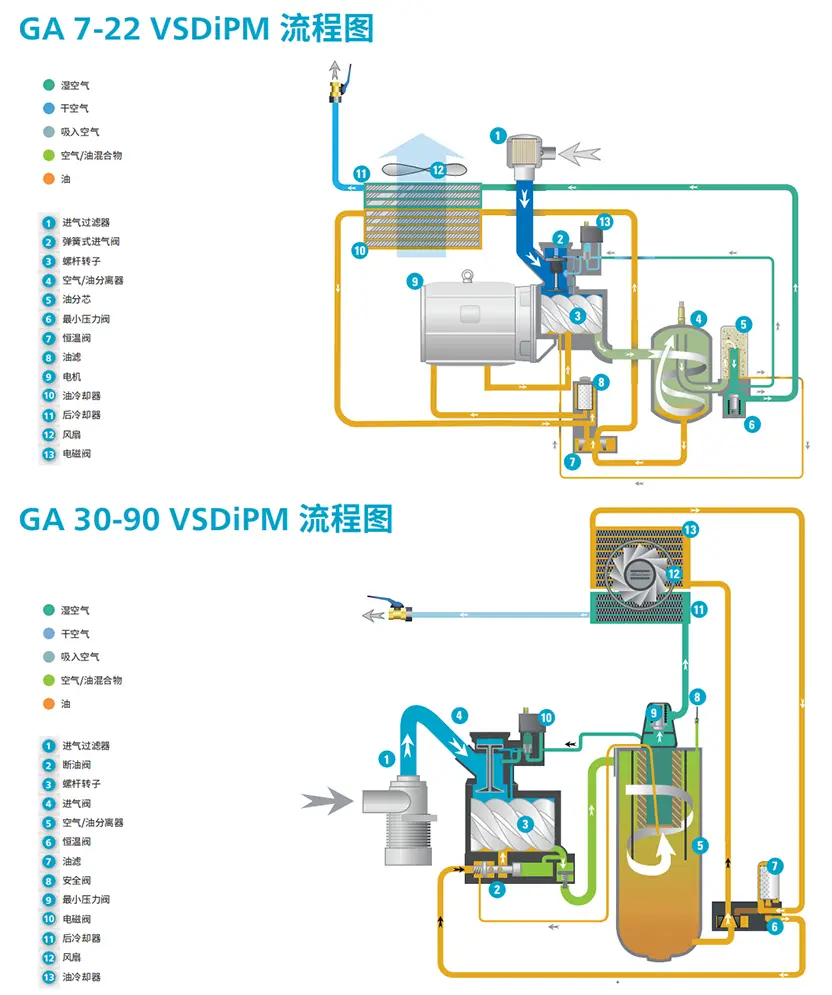

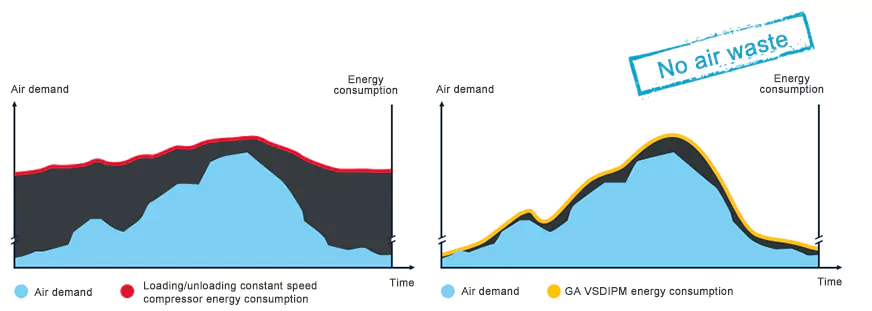

The variable-speed drive technology of the G7-22 VSD enables the motor speed of the compressor to match your air demand.

Compared with traditional loading/unloading machines, VSD Variable Frequency Air Compressor can save up to 35%* of energy. In addition, the oil-cooled permanent magnet motor of GVSD can start and stop under the full system pressure without unloading. It also eliminates the peak current impact during startup.

① Smaller floor space

The VSD Variable Frequency Air Compressor saves more installation space and can install more machines within the limited space.

② Screw host

· Asymmetric rotor profile and carefully selected bearings.

· High-performance rotors significantly reduce operating costs.

③ Efficient cooler

The exhaust temperature of the machine head is within a reasonable range, reducing the downtime losses caused by high temperatures.

The core of the stainless steel water cooler has stronger corrosion resistance.

The optimized design reduces maintenance costs and ensures more reliable performance.

④ High-efficiency oil and gas separator

Reduce pressure drop and lower energy consumption.

Low fuel consumption, reduced maintenance costs, and longer service life.

The optimally designed oil and gas separator reduces the oil content and enhances stability.

⑤ High-efficiency motor

The high-efficiency IE3 motor (F-class insulation) can ensure continuous normal operation even in harsh environments.

It can also ensure long-term stable operation in harsh environments.

⑥Elektronikon's MK5&SmartLink control system

Clear and straightforward instructions enable you to master important Settings and data more quickly.

Monitor the operation and maintenance status of the equipment.

SmartLink can remotely monitor the operating status of the compressor.

⑦ Convenient installation, use and maintenance

No foundation required for the chassis, easy to install.

Fully integrated, silent hood.

Convenient for transportation and simple to maintain.

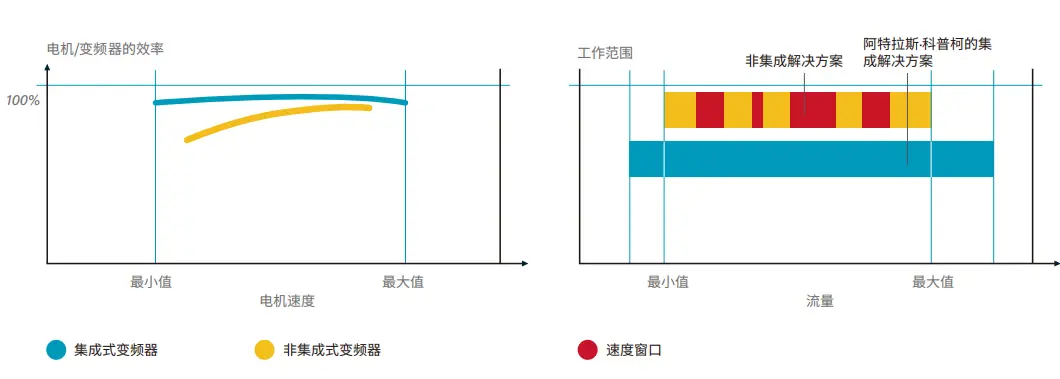

Atlas: What are the unique features of Copco's integrated G(L)VSD?

1.Elektronikon can control the compressor and the integrated frequency converter, thus ensuring the safety of the equipment.

2. The working pressure can be freely selected from 3.5 to 10bar, thereby reducing electricity costs.

3. The frequency converter and motor are specially designed (equipped with bearing protection) to achieve high efficiency within the allowable speed variation range.

4. The specially designed variable-frequency motor is sufficient to meet the cooling requirements of the motor and the compressor.

5. All Atlas Copco G(L)VSD compressors have undergone EMC testing and certification. The operation of the compressor will not affect external devices, and vice versa.

6. Specifically designed for mechanical improvements, it eliminates the worry of vibration within the frequency conversion range.

7. Eliminate the "speed window" that is not conducive to energy conservation and stable working pressure. The gas volume adjustment range is 30% to 100%.

8. The pressure band of the pipeline network is maintained within the range of 0.10 bar and 1.5 psi.

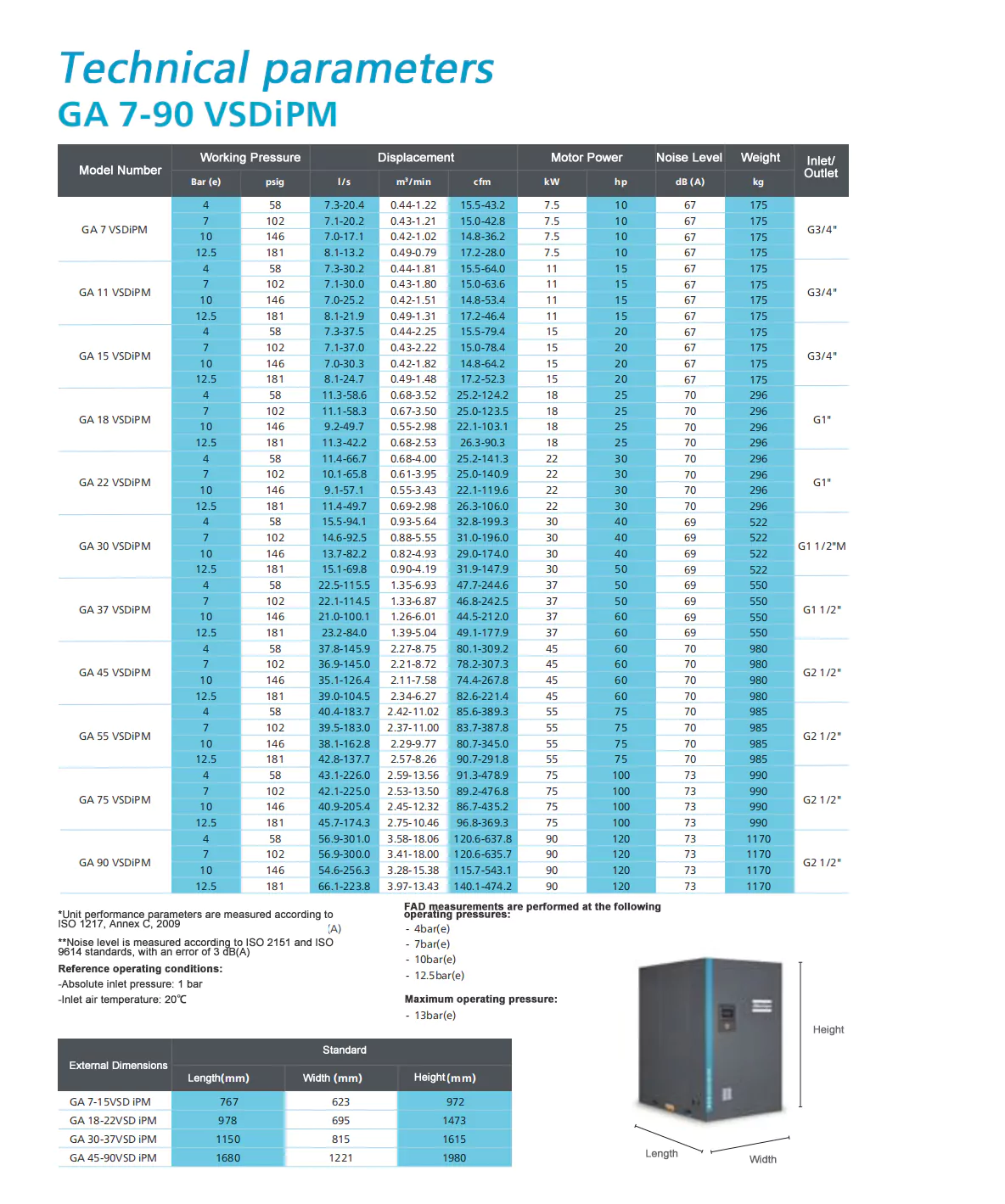

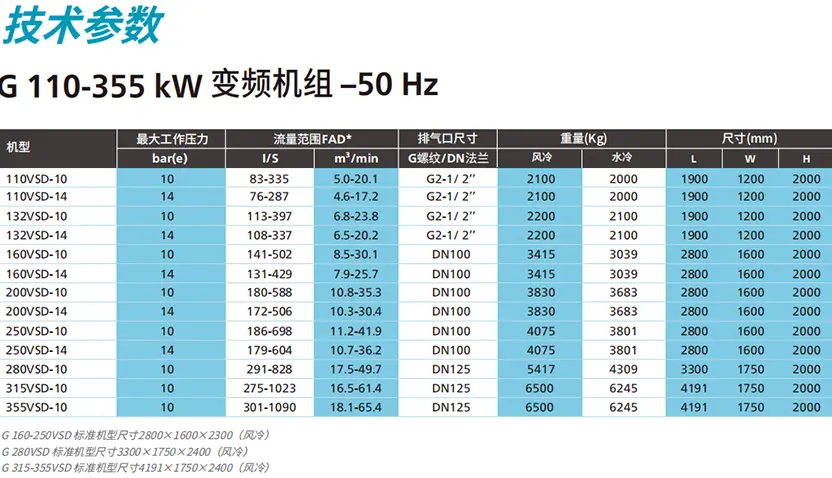

Efficient

The highly efficient VSDiPM series compressors save an average of up to 35%* of energy compared to compressors driven at specified speeds

The motor efficiency grade is equivalent to the IE4 standard, with direct drive, further reducing energy efficiency loss

The unique intake valve design minimizes intake pressure drop and air loss

Intelligent

Compressor dedicated frequency converter, variable speed regulation to meet the operation requirements of different working conditions

The Elektronikon touchscreen controller makes monitoring and maintenance much simpler

The modular design meets different performance requirements and a high material utilization rate

Reliable

The fully enclosed variable frequency drive chain design ensures reliable operation in harsh environments

Modular design, using reliable components that have been verified on mature models

The cooler adopts a corrugated fin design, which can ensure stable heat dissipation of the machine even in harsh environments

Atlas Copco compared multiple devices and conducted long-term tests to conclude that the GAVSD IPM saves an average of over 35% more energy than the GA fixed-frequency model.

GA7-22 VSDiPM

Exquisite drive, intelligent control

The GA30-90VSDiPM is a truly energy-saving inverter air compressor for you. Its innovative drive system and dedicated inverter design for air compressors can save you up to 35% of energy, ensuring sustainable production and significantly reducing your operating costs.

① Permanent magnet (iPM) motor

· The efficiency level is equivalent to the IE4 standard

· The special oil passage design makes the cooling more efficient

· The motor has a protection class of IP66 and an insulation class of H

· Oil-cooled motor, no cooling fan required

② Compressor rotor

· Designed and manufactured by Atlas Copco

· Reliable, efficient and quiet

③ High-efficiency drive system

· Efficient and reliable direct drive (GA45-75VSDIPM)

· Innovative gear transmission system, easy to maintain (GA90VSDIPM)

· Fully sealed oil-cooled motor

④ Classic cooling system

· Independent oil cooler and aftercooler

· The corrugated fin design ensures the stable operation of the compressor in harsh environments

· High-flow axial fans ensure superior cooling performance

· Lower temperatures ensure efficient operation

⑤ Robust oil filtration/oil separation system

· The oil filter is equipped with a bypass valve

· Spinning design, easy to maintain

⑥Elektronikon Touchscreen controller

· It is equipped with an intelligent algorithm to optimize system pressure and reduce the energy consumption of the entire machine

· Remote control, alarm output, maintenance and servicing plans, and network diagnosis are all available

· It is equipped with Smartlink remote diagnosis to monitor the real-time status of the system

⑦ Dedicated Neos frequency converter (suitable for GA 45-90 VSDiPM)

· Special frequency converter for permanent magnet variable frequency air compressors

· Protection grade IP5x

· The sturdy aluminum casing ensures stable operation under harsh conditions

· Modular design, compact structure, simplicity and user-friendliness

Atlas Copco's VSDiPM series can automatically adjust the motor speed to precisely control and meet customers' gas usage requirements. Compared with compressors driven by the specified speed, the VSD Variable Frequency Air Compressor saves an average of up to 35% of energy.

When the gas demand fluctuates sharply (20%-100%), the average energy saving can reach up to 35%*

The Elektronikon® controller smoothly adjusts the motor speed in response to pressure fluctuations

There is no waste from idling or letting go

The compressor can start/stop at full pressure without any unloading waste

There is no peak starting current, and it has no impact on the power grid

Through in-depth investigation and measurement, it was found that the demand for compressed air in most production environments fluctuates sharply on a daily, weekly and monthly basis, and the gas supply of compressors also changes dramatically along with the fluctuations in the demand for compressed air.

Atlas Copco compared multiple devices and conducted long-term tests to conclude that the GAVSD IPM saves an average of over 35% more energy than the GA fixed-frequency model.