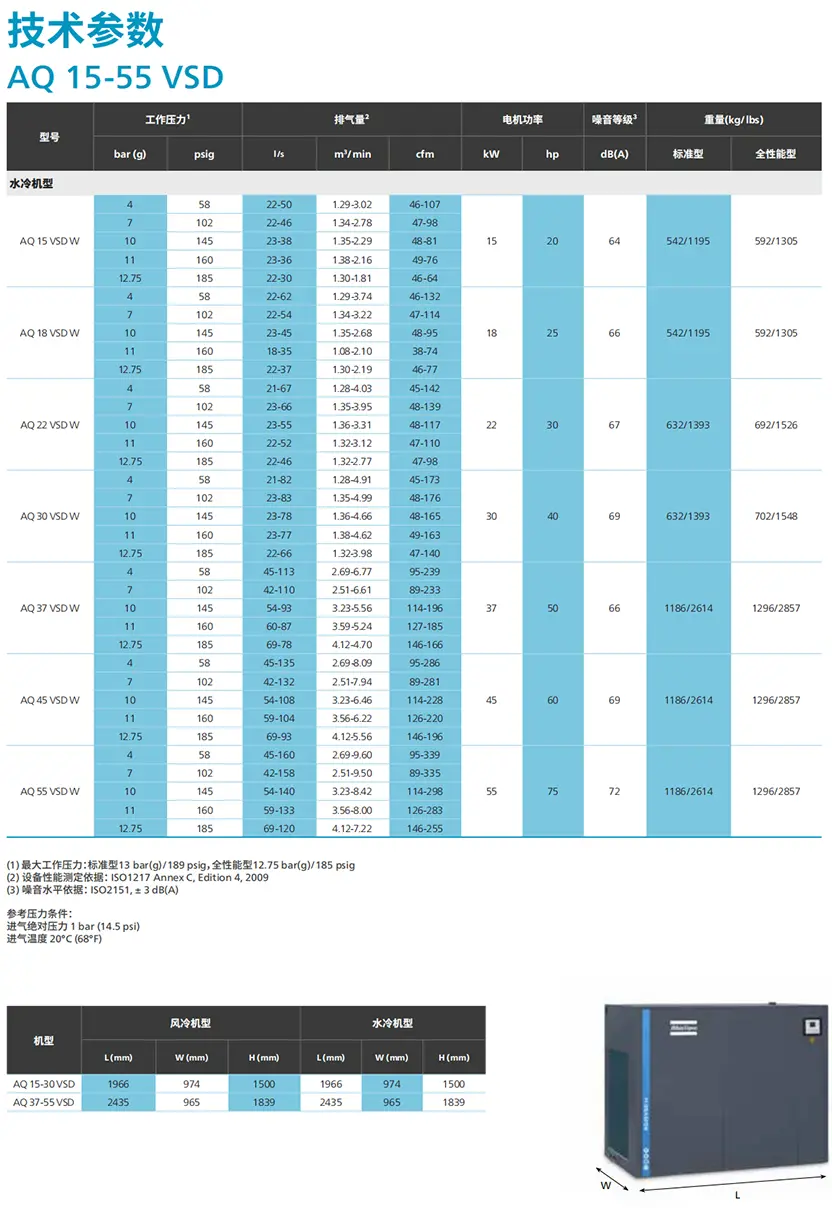

Atlas' s VSD Oil-Free Water-Lubricated Air Compressor has obtained ISO 8573-1 class SO oil-free certification, meeting your oil-free air requirements while achieving excellent energy efficiency. Our oil-free compressors eliminate all possible risks of oil contamination and always protect your production applications. We are a professional air compressor manufacturer and supplier in China. Welcome to consult and purchase.

Powerful oil-free compressed air

Pure, oil-free compressed air means that there is no compromise in air quality.As an expert in water lubrication technology, Atlas Copco has introduced a wide range of oil-free compressors over the past decades, supplying 100% oil-free compressed air. AQ compressors are ISO 8573-1 CLASSO oil free certified and achieve excellent energy efficiency while meeting your oil free air needs.

Zero pollution risk

Whether in pharmaceuticals, food and beverage, precision electronics, or other demanding industries, air quality is critical to final products and production processes.Atlas Copco's AQ VSD Oil-Free Water-Lubricated Air Compressor eliminates all possible risks of oil contamination.

lower energy costs

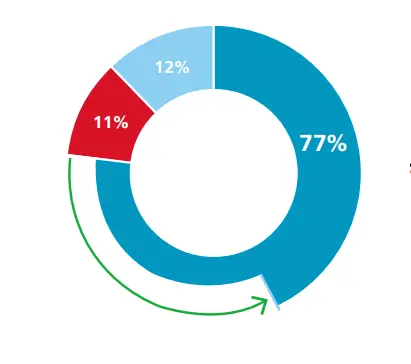

Energy costs account for 70% of compressor life cycle costs (LCC), and their importance is evident.Efficient compressed air solutions optimize pressure, flow and air treatment equipment for different processes.Atlas Copco's AQ compressors offer the ideal all-in-one solution to reduce your electricity bills.

Renowned expertise

Atlas Copco has been leading the way in oil-free compressed air technology for more than six decades thanks to its extensive experience and continuous technological innovation.Its AQ series compressors are designed to provide the ideal oil-free compressed air to protect your production applications at all times.

Ingenious to meet your needs

At Atlas Copco, we are committed to providing compressed air solutions that meet or exceed your expectations. The integrated VSD Oil-Free Water-Lubricated Air Compressor inherits Atlas Copco's decades of experience in designing and manufacturing oil-free compressors.

① Water lubricated rotor

Isothermal compression (very low rotor outlet temperature) for high energy efficiency

● True water lubricated rotor

● Water lubricated bearings

● Working pressure up to 13 bar

② Water filter

Ensure a continuous supply of clean water

● 10 micron filtration capability maintained over life cycle

③ Heavy duty air filter

●99.9% removal of dust particles as small as 3 microns, adequate protection of compressor components

● Differential pressure indication enables preventive maintenance to reduce pressure drop

④ Water separator

● Stainless steel water separator, using centrifugal force and gravity to achieve separation

● Includes 3 sensors to achieve accurate water level adjustment

⑤Efficient drive motor

●IP55 drive motor, flange mounting to ensure accurate alignment

● Combined with direct drive to achieve excellent energy efficiency

⑥Reverse osmosis system

Built-in reverse osmosis system provides reliable high-quality water for continuous stable operation

⑦ Fan and water cooler

● All series have air-cooled or water-cooled models available

● Thanks to the built-in cooler, saving installation and floor space

● Water-cooled compressor keeps dryer inlet air temperature below 55 ° C (131 °F)

⑧Efficient built-in dryer

● Excellent air quality

● 50% lower energy consumption compared to traditional dryers

●Zero ozone layer destruction

⑨Elektronikon° Color screen intelligent controller

● Advanced Elektronikon° color display intelligent controller designed for integration into (remote) process control systems

⑪Soundproof cover

●The acoustic enclosure design makes it suitable for most installation environments, eliminating the need for a separate compressor room

⑫Innovative Neos inverter

●IP5x protection level

●VSD Oil-Free Water-Lubricated Air Compressor features rugged aluminum housing for trouble-free operation under harsh conditions

● Fewer parts: compact and easy to use

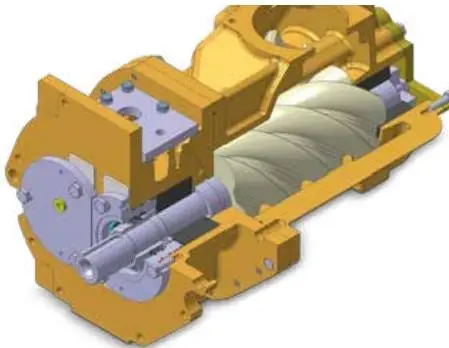

Mature technology

AQ series compressor core-unique water injection twin screw rotor, efficient operation closer to isothermal compression.Ultra-high strength polymer composite rotor, optimized rotor profile and water-lubricated bearings ensure that the rotor is not contaminated by oil and produce pure oil-free compressed air.

Twin screw rotor

High-quality ultra-high strength polymer composite rotors with optimized profiles for efficient compression.Anti-corrosion and highly efficient raw materials and true water spray lubrication result in a longer service life.

Rotor housing

The VSD Oil-Free Water-Lubricated Air Compressor is made of aluminum bronze with a corrosion-resistant housing for strength and durability.

Bearing

There is no physical contact inside the hydrodynamic bearing, only sliding through the water film, no grease lubrication, to ensure a long service life.

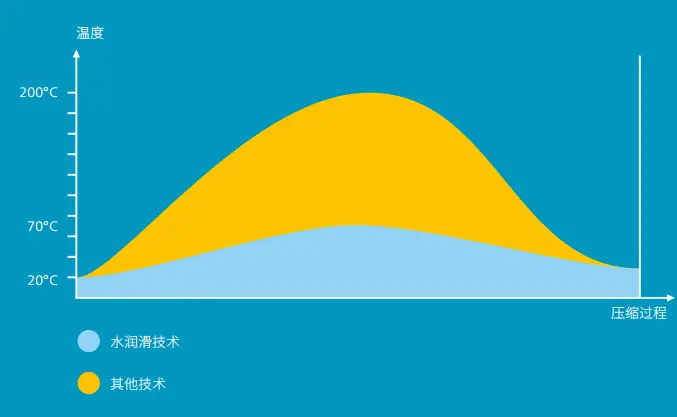

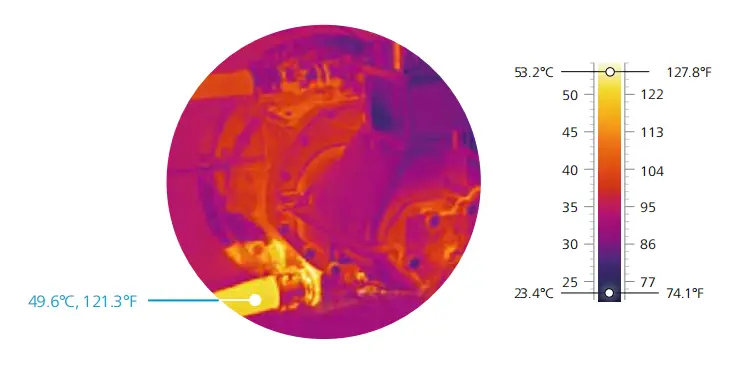

Compression efficiency of water lubrication

Water has excellent cooling power and effectively removes heat from the source.Energy waste caused by heat generation is eliminated, and more compressed air can be produced per kilowatt of energy.The cooler compressed air reduces thermal stress on the components, thereby extending service life.

Excellent water lubricated rotor

·Increase exhaust volume

·Reduce unit energy consumption

·Near isothermal compression

·Pressure ratings of 7, 10 and 13 bar.

·The efficient cooling capacity of water, combined with precise design, ensures AQ's superior energy efficiency.

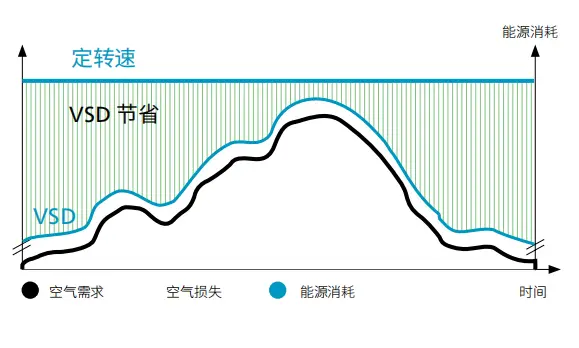

VSD: Cutting Energy Costs

Compressor energy consumption accounts for more than 70% of the entire life cycle cost, and the production of compressed air consumes more than 40% of the total electricity bill of the plant.To reduce energy consumption, Atlas Copco developed the VSD Oil-Free Water-Lubricated Air Compressor.VSD technology not only saves a lot of energy, but also protects the environment for future generations.Thanks to its continuous investment in this technology, Atlas Copco offers a wide range of variable speed drive (VSD) air compressors on the market.

VSD: Energy consumption fluctuates with gas demand

● 35% average energy saving in production processes with dramatic changes in gas demand

Elektronikon° color screen controller controls motor speed and inverter

● No idle and empty waste

● Special design VSD motor, can start/stop at full pressure, no unloading waste

● Eliminate peak starting current

● Low operating pressure reduces system leakage

● EMC electromagnetic compatibility in accordance with standards (2004/108/EG)

Constant speed: non-adjustable energy consumption

Traditional constant speed compressors have only one speed and are 100% open.This results in a significant waste of energy when demand is low.

Up to 35% energy savings

Atlas Copco's AQ VSD technology tracks customer gas usage changes and adjusts compressor speeds in real time, achieving average energy savings of up to 35 percent and total lifecycle cost savings of approximately 22 percent.

Total compressor life cycle cost

● Energy consumption cost

● Energy savings from VSD

● Equipment purchase cost

● Maintenance costs