We have our own factory and are a professional manufacturer and supplier of Oil-Free Scroll Air compressors in China. We have a variety of Ingersoll Rand Air Compressor products. Welcome to consult!

Your Trusted Partner in Compressed Air

Staying ahead of your competition with advanced compressed air systems and services that boost productivity, lower operating expenses and extend equipment life is critical to your success.

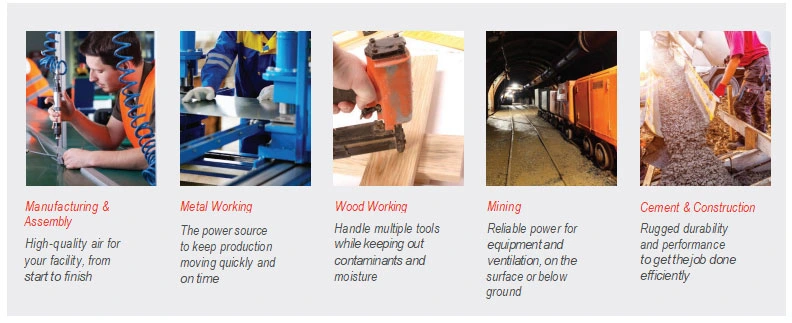

No matter the industry or application, you can count on Ingersoll Rand® as a trusted partner for oil-flooded compressed air technologies and services. By focusing on you and your business, we provide collaborative solutions that make you successful,offering a total system approach to maximise efficiency and performance.

Take a Systems Approach

Delivering reliable oil-flooded compressed air to your facility goes well beyond the compressor itself. Optimise total cost of ownership (TCO) through a systems approach that employs the best air compression technologies to deliver reliability for life—from design to decommissioning.

Your business will benefit from Ingersoll Rand’s partnership through our extensive experience and global expertise to ensure reliability, lower maintenance costs, ease of serviceability and system optimisation.

Air quality plays a decisive role in many situations. The presence of solid particles, water vapor, oil, and oil vapor in compressed air systems can lead to downtime, product damage, and even product recalls, damaging brand reputation and, worse, consumer and product credibility.

Reliable product and system designs deliver superior air quality, protecting sensitive downstream air-using equipment, reducing maintenance, and extending equipment life.

Improved Productivity: Using certified oil-free, zero-grade compressors ensures zero air pollution, eliminating the risk of product damage and waste.

Enhanced Maintainability: Our oil-free equipment is specifically designed for easy maintenance and has easy access to consumable components.

Reduced Lifecycle Costs: While oil-free systems have higher initial costs, their lower operating and maintenance costs over their entire lifecycle offset these costs, while maintaining superior air quality.

Ingersoll Rand offers a wide range of reliable oil-free products, ensuring there's one to suit your industry and application. We will evaluate and recommend more suitable oil-free solutions to improve plant productivity, thereby delivering a final product with zero contamination risk.

When quiet operation, low maintenance, and a small footprint are critical, scroll air compressors are the wise choice. Their compact, innovative design makes them ideal for many commercial applications requiring reliable, oil-free air.

Oil-Free Scroll Air Compressors deliver compressed air through the relative rotation of two scroll plates.

1、A rotating scroll plate revolves around a fixed scroll plate.

2、The space between the two scroll plates gradually decreases as they rotate towards the center, compressing the air.

3、This process repeats continuously to maintain suction.

4、Once the air reaches the center, it is discharged through the outlet.

|

Smaller footprint |

Smaller floor space |

|

Fewer components |

Higher reliability, longer lifespan, less maintenance |

|

Lower noise level |

Healthier working environment |

|

100% oil-free |

Suitable for any industry |

|

Fewer consumables |

Longer maintenance intervals and service life |

|

No metal-to-metal friction |

Less maintenance |

|

Zero emissions |

Meets sustainability goals |

|

Fewer moving parts |

Less vibration |

100% Oil-Free Air

Oil-Free Scroll Air Compressor employs a simple blade-end seal design, ensuring no metal-to-metal contact exists at any point. Therefore, this technology requires no lubrication, thus ensuring the production of high-quality oil-free air.

Advantages of our oil-free scroll compressor

High-efficiency design and control

Our scroll compressors offer higher flow rates per kilowatt and single-stage compression pressures up to 10 barg. We achieve this high efficiency through the following design features:

■ Start-up/stop control reduces idle energy waste

■ Dual-inlet compressor design ensures stable and efficient compression

■ Aluminum casing reduces overall product weight

Modular design.

The multi-flow design improves efficiency under low-load conditions, meaning you can precisely control the number of operating compressors to match your needs.

Cooling Operation

Large fans ensure low-temperature operation and extend component life.

Microprocessor Control

Manages exhaust pressure to meet your air requirements while measuring key operating parameters to reduce unexpected downtime.

Lower Exhaust Temperature

A lower CTD aftercooler results in lower exhaust temperatures, reducing aftertreatment intake temperatures and lowering aftertreatment investment costs by selecting a smaller aftertreatment setting.

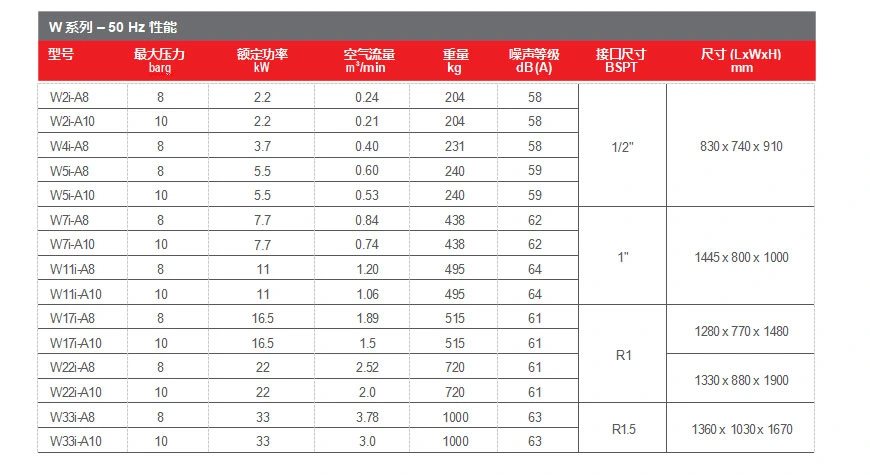

W Series Product Configuration and Performance

Air Inlet Filter (Replaceable Filter) Pressure Gauge*

Start/Stop Switch* Automatic Start/Stop Operation*

Power Indicator Light* Control Voltage Starter with Motor Overload Protection*

High Temperature Shutdown with Indicator Light* Air-Cooled Aftercooler

Running Timer* Robust Motor, Specifications Meet Operating Requirements, with Water Ingress Protection

Ingersoll Rand offers a wide portfolio of reliable products that will adapt to your industry and application. We will assess and propose the best solution to lower the total cost of ownership of your compressed air system, maximising the productivity of your operation.

Oil-Free Scroll Air Compressor use accounts for a significant part of your energy costs. Our design team used advanced computer modeling techniques to create rotary screw compressors that maximise efficiency and airflow, while operating reliably to improve your company's bottom line.

What Makes Our Rotary Screw Compressors Unique?

World-class single and two-stage airends (two-stageavailable starting at 90 kW), along with a TEFC induction or optional variable speed motor minimise energy use.

Leak-free Designs

V-Shield™ technology provides a totally integrated, leak-free design, featuring PTFE stainless steel braided oil hoses and O-ring face seals.

Intuitive Control

RSi / IE comes standard with the Xe-Series controllers deliver increased control and functionality through an intuitive user interface as well as remote access with any common, current web browser.

Rn / NE comes with a new generation Luminance controller integrated with LoT for more powerful functions.

Adaptive Monitoring

Progressive Adaptive Control (PAC™) monitors key operating parameters and continuously adapts to prevent unexpected downtime.

Advanced Cooling Systems

A free-floating cooling system allows heat exchangers to expand and contract, reducing thermal stress for improved system durability.

Integrated, Compact Design Options

Optional Total Air System (TAS) provides clean, dry air in a single package that minimises installation costs and reduces footprint.

World-Class Efficiency

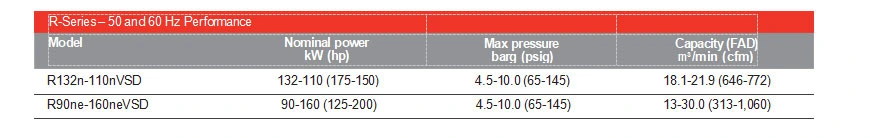

Our Next Generation R-Series compressor includes an all-new, state-of-the-art airend, making it your best choice for performance. The new airend improves efficiency through several advancements, including an optimised rotor profile to help minimise operating expenses.

The new rotor profile also provides world-class airflow. With more airflow for the same power input, your compressor requirements are smaller, reducing both investment costs and energy usage. For 90-160 kW models, improve performance even more with our optional two-stage airend for increased flow capacity and power gain.

Efficiency for Constant Demand: Fixed speed compressors featuring the reliable and efficient IE3 TEFC induction motor (RS models only)

Efficiency for Variable Demand: VSD compressors with the highest efficiency motor available

Premium Efficiency for Constant Demand: Fixed speed compressors with the continuous duty IE3 TEFC induction motor and enhanced features for improved performance and efficiency

Premium Efficiency for Variable Demand: VSD compressors with enhanced features for improved performance and efficiency