Ingersoll Rand is committed to providing customers with advanced compressed air systems to enhance production efficiency, reduce operating costs and extend equipment lifespan. Each RM Screw Air Compressor adopts a reliable and efficient design, featuring industry-leading performance, achieving outstanding energy efficiency, excellent reliability and ideal air output. We are a professional manufacturer and purchaser of Air Compressor in China. Welcome to consult and purchase.

The new RM series oil-lubricated screw air compressors will give your business a boost.

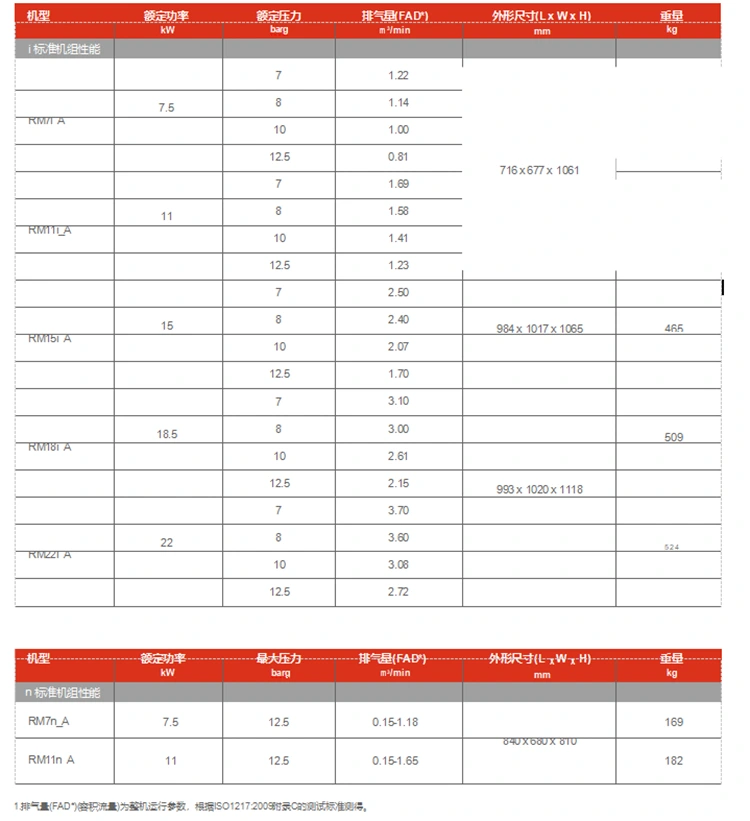

7-22 kW

Ingersoll Rand is committed to providing customers with advanced compressed air systems to improve productivity, reduce operating costs, and extend equipment life. Their superior performance is suitable for a wide range of industries. Each RM Screw Air Compressor features a reliable and efficient design, boasting industry-leading performance, achieving excellent energy efficiency, outstanding reliability, and ideal air output. Furthermore, leveraging our unique advantages, we also provide comprehensive solutions including professional engineering design and construction, full after-sales support, and durable Ingersoll Rand genuine spare parts.

The new RM series oil-lubricated screw air compressors will give your business a boost.

Global Presence, Local Service

Highly Efficient Operation and Powerful Information Communication

We Improve from the Core

In the development of the new RM series, we adopted a highly advanced new main unit, providing you with a superior performance option. Through improvements such as optimized rotor profiles, the new main unit achieves up to

an 11% increase in efficiency, minimizing operating costs. Furthermore, the new rotor profile offers ideal exhaust volume, up to 11% higher than previous models. Lower power-to-weight ratio means lower equipment investment costs and energy consumption, reducing your overall costs.

Technology is power.

A high-quality compressor not only supplies air but also provides essential operating parameters. Therefore, each RM series compressor is equipped with an intelligent controller that monitors key operating points and adjusts system parameters to extend uptime and reduce energy consumption. Wherever you are, you can monitor the compressor's operating status in real time and take timely action.

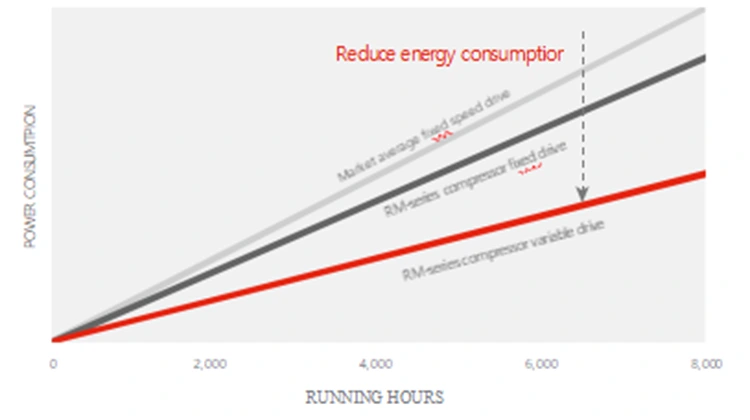

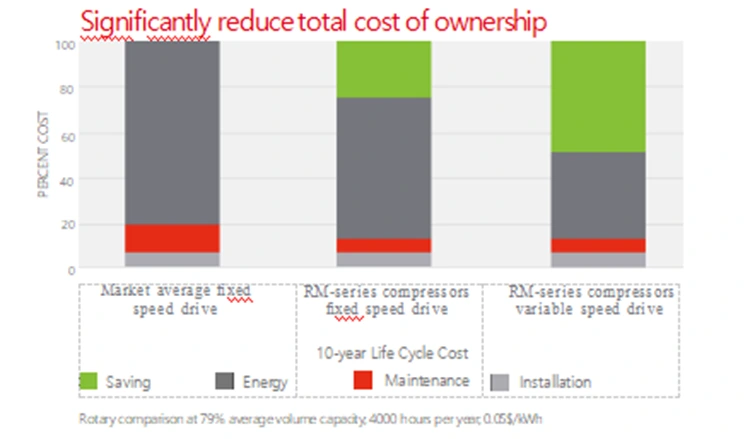

Green and environmentally friendly, energy-saving and efficient

The RM Screw Air Compressors all adopt a brand-new high-efficiency main unit, combining fixed-frequency IE3 and ECO*-PM permanent magnet inverter IE5 energy-efficient motor technologies, which can save you up to 12-30% on electricity costs.

The name ECO is a combination of Environment, Conservation, and Optimization, reflecting the fundamental design and development principles of environmental friendliness, energy efficiency, and economy. These three performance characteristics are also the qualities that ECO permanent magnet motors consistently pursue, aligning with Ingersoll Rand's strategy and the goals of the Paris Agreement.

Luminance Series Controllers

Ingersoll Rand's new generation of Luminance controllers boasts powerful control and remote management capabilities, ensuring stable compressor operation while significantly improving compressor operating and management efficiency.

Le Controller Features

Controller Features

More User-Friendly Interface

High-resolution touchscreen display

More intuitive display of key parameter information

More Advanced Algorithms

Advanced controller algorithms result in smaller pressure fluctuations and lower energy consumption

Synchronous control of up to 4 Luminance-equipped compressors without any additional system controllers

More Efficient Management

Built-in internet connectivity for remote and efficient management of unit operation status and maintenance plans

Automatic push notifications of warnings, fault alerts, and performance reports

Easier Upgrades

Modular design facilitates software function iteration and upgrades, continuously improving the user experience

More Stable Performance

Adopts a fully isolated design with stronger anti-interference capabilities and enhanced electromagnetic compatibility

Adaptable to various environmental conditions, with a service life of no less than 5 years or 40,000 hours

More Powerful Core

Multi-core processor significantly improves computing speed and communication capabilities

Significantly reduces data acquisition and operation interface latency, ensuring more timely communication

PackageCARE: when the agree- ment becomes efective, all operating risks transfer from you to us to free you from any concerns.

You will enjoy 100% operating risk transfer for any machine model and life.

PlannedCARE: all-round genu- ine spare parts and maintenance services

You will enjoy preventative diagnosis, current state analysis & trend judgment; 10 years ' airend warranty (for new oil-flooded rotary screw air com- pressor)

PartsCARE: genuine spare parts

for daily maintenance

You will enjoy regular shipment of spare parts and daily mainte- nance reminder, 5 years' airend warranty (for new oil-flooded rotary RM Screw Air Compressor)

Optimized internal structural design

High Efficiency

The newly designed high-efficiency main unit improves efficiency by up to 11% and air volume by up to 11%, while ensuring long-term reliable operation.

Reliable

It can remove lubricating oil from compressed air to below 3-5 ppm, thereby protecting downstream equipment, extending filter life, improving productivity, and reducing customer maintenance costs.

Robust

V-shieldTM technology uses plane-sealed O ring that helps deliver repeatable, leak-free connec- tions.

cient /

Superior In Productivity

The air intake system with large-allow- ance inlet air and low pressure drop air filterefectively reduces inlet air pres- sure and improve ciency of the unit, and reduces maintenance work and cost to facilitate the production for customers.

Reliable

Fixed Frequency: Equipped with an IEC60034-30 standard IE3 high-efficiency motor. Protection rating reaches IP55, achieving Class F insulation and Class B temperature rise.

Variable Frequency: Equipped with a high-efficiency IE5, IP66 oil-cooled permanent magnet variable frequency motor, achieving Class H insulation and Class B temperature rise.

A horizontally parallel, non-welded oil cooler mounted on top of the unit reduces deformation and leakage caused by thermal stress, improving reliability, extending service life, reducing maintenance, lowering customer operating costs over the unit's lifecycle, and increasing production efficiency.

High-Efficiency Operation and Powerful Information

We Start from the Core

We developed the new RM series using state-of-the-art compressor units, designed to provide you with superior performance. Through optimized rotor profiles and other improvements, the new compressor unit achieves an 11% increase in efficiency and a significant reduction in operating costs. Furthermore, the new rotor profile achieves ideal air capacity, 11% higher than the previous generation. Lower power-to-weight ratio means lower equipment investment costs and energy consumption, thus reducing your total cost of ownership.

Technology as Power

High-quality compressors deliver the necessary operating parameters while supplying air. Therefore, each RM series compressor is equipped with an intelligent controller to

monitor key operating points and adjust system parameters, thereby extending uptime and reducing energy consumption. Wherever you are,

you can

understand the RM Screw Air Compressor's operating status in real time and take necessary actions promptly.

For greater energy efficiency,

each RM series air compressor is equipped with a brand-new, high-efficiency main unit, combining an IE3 fixed-speed motor and ECO*-PM VSD IE5 variable-frequency motor technology, helping you save up to 12-30% on energy costs.

ECO (Environment, Energy Saving, and Optimization) adheres to the fundamental R&D philosophy of environmental protection, energy saving, and economy. These three characteristics are also the continuous pursuit of ECO PM motors, aligning with Ingersoll Rand's strategy and the goals of the Paris Agreement.