Dechuan can provide a full range of membrane dryers.A complete range of dual-tower adsorption air dryers and blower dryers, suitable for various industrial applications. We are a professional Post-processing Equipment manufacturer and supplier in China. Welcome to consult and purchase.

Adsorption Air Dryers

A complete range of dual-tower air dryers and blower dryers, suitable for various industrial applications.

Protect Your Systems and Processes

Adsorption air dryers are highly efficient and energy-saving, providing very low dew points.

Suitable for a Variety of Industry Applications

A comprehensive range of air dryers is available for various industries and applications with dew points as low as -70°C/-100°F.

Protect Your Production

Our Elektronikon control and monitoring system continuously monitors your adsorption air dryers, ensuring optimal productivity and efficiency in your work environment.

How do adsorption air dryers work?

What is the working principle of a dual-tower air dryer?

Adsorption dryers are used when compressed air applications require a pressure dew point below 0°C. This regenerable adsorption dryer typically consists of two containers, both filled with desiccant. One container removes moisture from the compressed air.

Humid air flows directly through the desiccant layer used to adsorb moisture. When this container becomes saturated, a valve switches the air and directs it to another, standby container. While adsorption continues in the other container, the first container is regenerated. This is a cyclical process.

The desiccant's moisture adsorption capacity is limited, and it must be dried or regenerated afterward. This requires depressurizing the adsorption tower containing the saturated desiccant and removing accumulated moisture.

The specific treatment method depends on the type of dryer.

Heatless dryer: Uses only compressed air for purging.

Purification blower dryer: Uses a combination of air supplied by an external blower, heat, and a small amount of compressed air.

Zero-purification blower dryer: Uses a combination of air supplied by an external blower and heat, without using compressed air.

Compression heat dryer: Uses compressed heat.

Heated purification dryer: Uses heat and a small amount of compressed air.

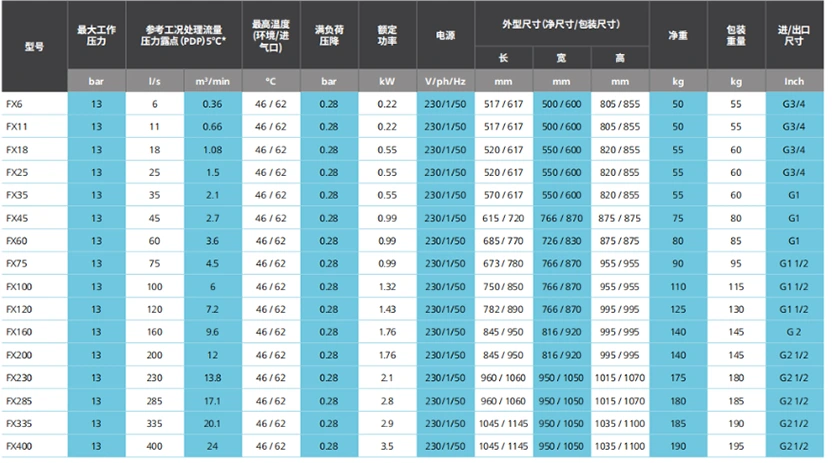

Membrane dryers

We offer a full range of membrane dryers.

Enhanced Reliability:

Water and oil particles in compressed air increase the risk of corrosion in air systems and pneumatic tools. Our membrane dryers significantly reduce these risks, improving system reliability and avoiding costly system downtime.

Reduced Energy Costs:

Treated clean air significantly reduces the risk of corrosion and leaks in your system. Even a leak as small as 3 mm can increase your annual energy costs by thousands.

Protecting Your Production:

Compressed air that comes into contact with the final product should not affect its quality. Our air treatment solutions provide clean, dry air that does not compromise the quality of the final product.

Smart Controller

Large LCD screen display, providing digital pressure dew point readings, monitoring dryer performance, and convenient to use.

Hot Gas Bypass Valve

Maintain cooling capacity under various operating conditions and keep a stable pressure dew point to avoid the risk of condensate freezing and blockage.

Capillary

Reduce the refrigerant pressure and temperature to improve cooling performance.

Refrigeration compressor

High-quality refrigeration compressor, equipped with high-pressure and start-up protection for safety.

Three-in-one heat exchanger

Provides an efficient and energy-saving three-in-one heat exchanger, integrating air/air, air/refrigerant, and water separator, with a compact size and reduced load loss.

Dual drainage function

The patented timed drain valve and float-type drain valve ensure the outflow of condensate.

Dedicated fan

Convenient air cooling with a larger heat exchange surface area to enhance the performance of the air dryer

Features and benefits

Provides high-quality dry compressed air to protect equipment and production, ensuring high operational reliability and smooth production

· Low pressure drop to reduce operating energy consumption

Uses environmentally friendly refrigerants to minimize environmental impact

Stable and reliable

•Reduce production failure rate

•Stable exhaust pressure dew point

•High-quality compressors, more energy-efficient

•Efficient and reliable heat exchanger

Reduce costs

•Longer lifespan

•Fewer maintenance parts

•Lower maintenance costs

Easy to install and operate

•Plug and Play

•Digital control, dew point display

•Reliable wall installation

Digital controller displays dew point temperature

•Easy to read

•Accurate dew point measurement, visualized monitoring

•Eliminate production losses caused by high dew points

Environmentally friendly

•Lower energy consumption

•Eco-friendly refrigerants R134a/R410a

The internal pressure drop is the difference between the pressure of the compressed air at the dryer inlet and outlet pipe.

The lower the internal pressure drop of the refrigerated dryer, the lower the pressure you need to achieve with the air compressor. And the less energy the compressor consumes.

Our refrigerant dryers are designed to minimize pressure drop and have therefore the lowest energy consumption.