Our HTA high-pressure air storage tanks are used to store compressed air to meet peak demand. This allows for a constant air pressure supply at all times while saving compressor energy and extending its lifespan. We are a professional Post-processing Equipment manufacturer and supplier in China. Welcome to consult and purchase.

Energy Savings for High-Pressure Applications

Atlas Copco's HTA high-pressure air storage tanks provide compressed air at a constant pressure by storing compressed air to meet peak demand. By avoiding excessive load/unload cycles, they save energy and extend the life of the air compressor. HTAs are ideal for high-pressure applications.

Suitable for various field conditions

The HTA can operate effectively in ambient temperatures ranging from -10°C/14°F to +55°C/131°F, and is suitable for handling humid and hot compressed air. A condensate drain is optional.

High reliability

We use the finite element dynamic calculation method to calculate resistance, stress, pulsation, and vibration, and design the HTA based on the calculation results, giving it outstanding reliability (CE 97/23 – ASME section VIII, div 3).

Technical Advantages

■Safe Selection

HTA gas tanks are easily compatible with compressors designed for 45 bar pressure and 55°C/131°F temperature.

■Robust Construction

Safe hot-dip galvanized metal tanks offer superior protection.

■Easy Installation

Equipped with easily accessible mounting holes for convenient installation.

What is an Air Receiver Tank?

Air receiver tanks, sometimes called compressed air storage tanks, are a crucial component of compressed air systems. Their primary purpose is to temporarily store compressed air to accommodate peak system demand and optimize plant operating efficiency.

The Role of Air Storage Tank

Theoretically speaking, your air compressor unit can operate without an air receiving tank. However, the absence of a component in the air system will increase the loading and unloading cycles of the compressor, imposing a heavier burden on it. It is important to remember that the loading and unloading cycle depends on the fluctuations in demand within your facility.

The Air Storage Tank plays a crucial role in pneumatic systems. They are used to store compressed air before it enters the pipeline system or equipment. In short, the air receiving tank acts as a buffer between the compressor and the pressure fluctuations caused by changes in demand.

Some air compressors are "tank-mounted", which means they are provided as a complete unit and installed on top of the air receiving tank. The use of tank-type air compressors not only saves space but also reduces the initial installation cost required for the installation of individual dryers. This configuration is very common in small air compressors, and the output power usually does not exceed 26 kilowatts (or 35 horsepower). Large air compressors are not suitable for tank installation designs as this would result in a top-heavy setup, potentially posing safety hazards.

The use of air receivers in pneumatic systems can reduce excessive circulation and ensure constant air pressure, which is crucial for maintaining the efficiency of compressors and extending their service life.

Types of Air Receivers

There are various types of air receivers to meet specific application needs. Among the most common are wet air receivers and dry air receivers.

Install a wet air receiver between the air compressor and the dryer. These storage tanks store untreated compressed air and help remove moisture before the air enters the drying system, playing a crucial role in enhancing the performance of the dryer. This step can ensure the improvement of the efficiency of the drying process.

On the other hand, the dry air receiver stores the processed compressed air and is usually installed after the air compressor and dryer. Their main function is to maintain the integrity of dry air and ensure the stable and reliable performance of the system.

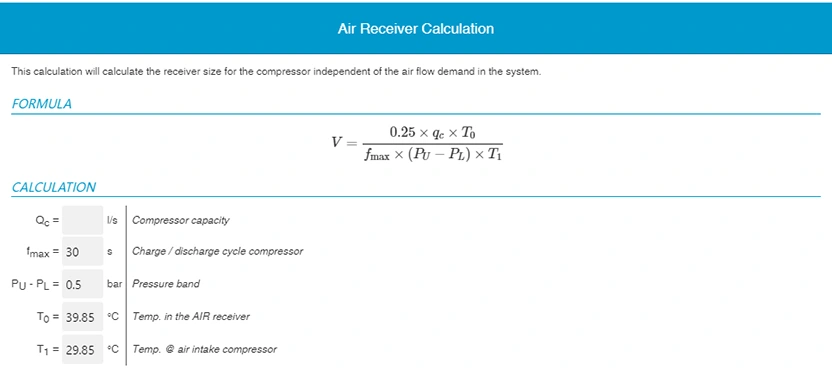

How to Properly Select an Air Receiver Tank?

A good rule of thumb for selecting an air storage tank is to allow 3-4 gallons of air per CFM flow rate, or 10-15 liters per liter of compressed air per second, depending on the type of air compressor used and the application. Similar to air compressor selection, several factors should be considered when determining the appropriate air receiver tank specifications for your system. The following factors are strongly recommended:

Minimizing pressure fluctuations/drops: The air receiving tank is used to minimize pressure fluctuations that may affect the production process and product quality. When choosing the right air receiving tank for your compressor, two values need to be noted: the output pressure of the compressor and the application requirements at the point of use. Please note that the compressed air stored in the air receiving tank is only useful when its pressure is sufficient to support the corresponding process. Therefore, the duration for which the air receiving tank supplies gas at the pressure required by the end user/equipment (in minutes) must be taken into account.

Meet Short-Term Peak Air Demands: If compressed air demand fluctuates dramatically throughout the day, peak demand must be considered to ensure that the system pressure does not drop below permissible levels. Air Storage Tanks provide storage to meet short-term peak air demands that the compressor cannot meet. Your air requirements can vary depending on the time of day, shift schedules, or even exceptional needs (such as occasional use of sandblasting machines or abrasive media jetting machines). A thorough understanding of your compressed air application, required airflow rate (CFM or liters per second), and the expected peak pressures of your system is highly beneficial, as this determines how much compressed air flow is needed to prevent air shortages in any part of the process.