The A series micro-heat regenerative adsorption dryers use a desiccant to adsorb moisture from compressed air. Each Slightly Heated Adsorption Dryer machine consists of two identical towers. They switch functions after each cycle. We are a professional Post-processing Equipment manufacturer and supplier in China. Welcome to consult and purchase.

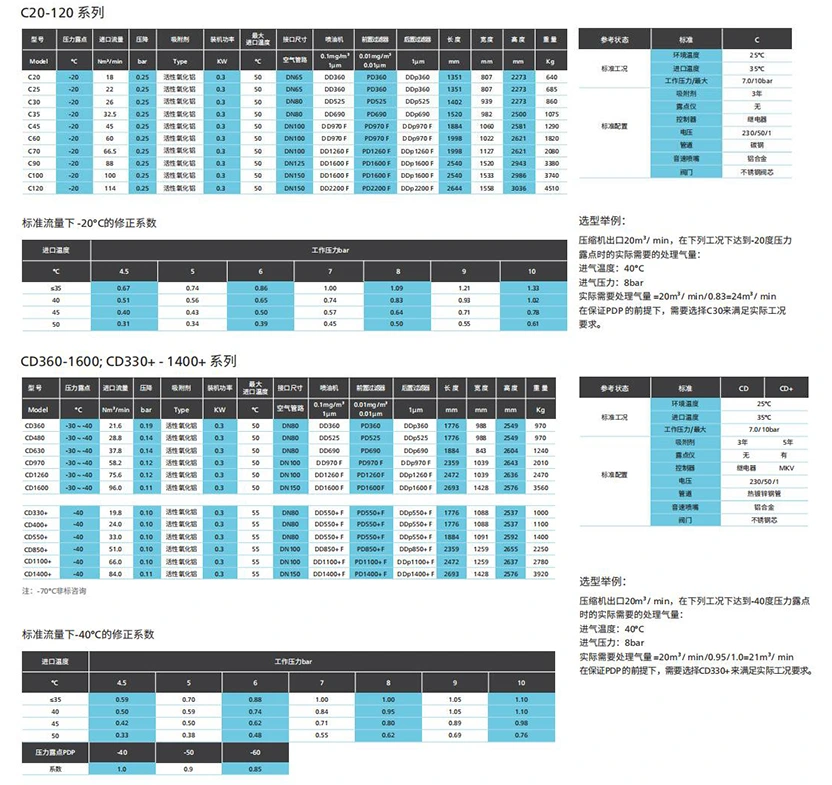

Micro-heat regenerative adsorption dryers A, AD, AD+

The A-series micro-heat regenerative adsorption dryers use a desiccant to adsorb moisture from compressed air. Each machine consists of two identical towers. They switch functions after each cycle.

While one tower is in adsorption mode, the other is in regeneration mode. Adsorbent regeneration consumes heat from an electric heater and a small amount of finished compressed air.

When using dew point control, the switching time is further extended, maximizing energy savings.

Depending on the pressure dew point, the desiccant can be alumina, silica gel, or molecular sieve materials. The lowest pressure dew point can reach -70°C.

■ The AD micro-heat regenerative adsorption dryer is suitable for medium-volume air applications.

■ Excellent energy efficiency comes from a low pressure drop design, high-efficiency adsorbent materials, and intelligent control of the electric heater.

■ High-end hardware configuration ensures stable and reliable performance. Minimal maintenance.

■ The inlet and outlet pipes can be freely reversed 180°.

■ The sonic nozzle is installed at the rear of the dryer to prevent the Slightly Heated Adsorption Dryer from overflowing. When multiple dryers are used in parallel, the air volume of each dryer is evenly distributed.

Technical data

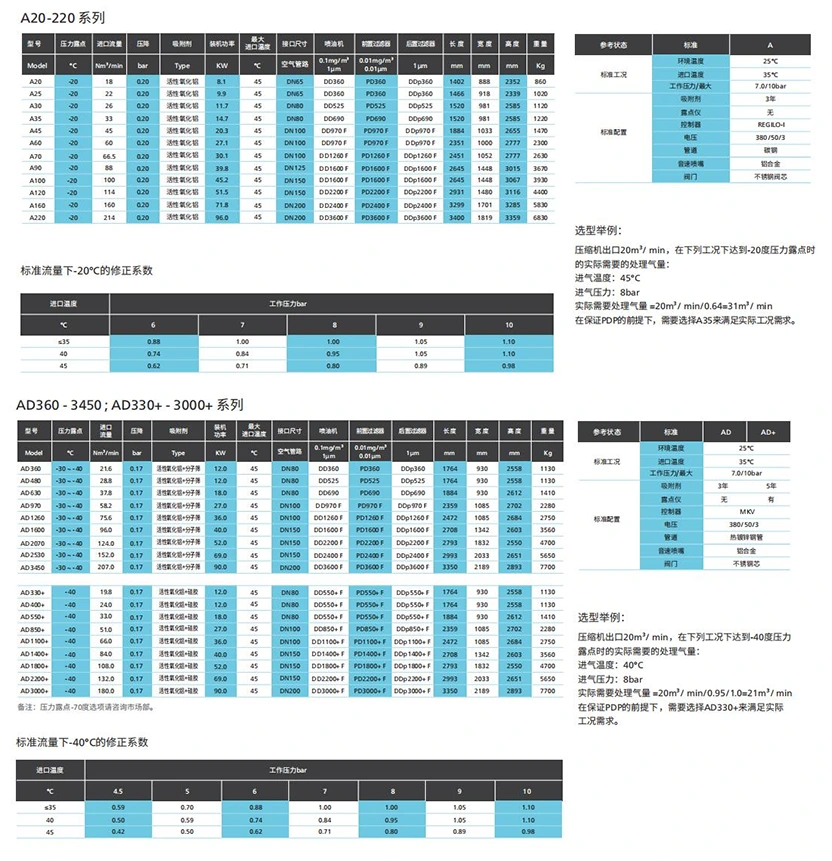

Heatless Regenerative Adsorption Dryer

Heatless Regenerative Adsorption Dryer C, CD, CD+

The C-series heatless regenerative adsorption dryers use a desiccant to adsorb moisture from compressed air. Each Slightly Heated Adsorption Dryer machine consists of two identical towers. They switch functions after each cycle.

While one tower is in adsorption mode, the other is in regeneration mode. The regeneration gas requires a certain proportion of finished compressed air.

When using dew point control, the switching time is further extended, maximizing energy savings.

Depending on the pressure dew point, the desiccant can be alumina or molecular sieve materials. The lowest pressure dew point can reach -70°C.

■ The C-series heatless regenerative adsorption dryer is particularly suitable for applications with small air volumes.

■ Excellent energy efficiency ratio comes from low pressure drop design and high-efficiency adsorbent materials.

■ High-end hardware configuration ensures stable and reliable performance. Minimal maintenance.

■ Inlet and outlet pipes can be freely reversed 180°.

■ The sonic nozzle is installed at the rear of the Slightly Heated Adsorption Dryer to prevent overflow. When multiple dryers are used in parallel, the air volume of each dryer is evenly distributed.

Technical data