Blower Zero Air Consumption Adsorption Dryer of DC Compressor uses a desiccant to adsorb moisture from compressed air. The machine consists of two identical towers. They switch between each other after a cycle. We are a professional Post-processing Equipment manufacturer and supplier in China. Welcome to consult and purchase.

Desiccant air dryers

Complete range of twin tower desiccant air dryers and rotary drum dryers for all industrial applications

Protecting your systems and processes

Desiccant air dryers provide the ultimate in energy efficiency and supply extremely low dew points

For a broad range of industrial applications

Complete range of desiccant air dryers for a broad variety of industries and applications with dew points down to -70°C / -100° F

Protect your production

Our patented Elektronikon control and monitoring system takes continuous care of your desiccant air dryers to ensure optimal productivity and efficiency at your site

How does a desiccant air dryer work?

Twin tower desiccant air dryer working principle

Blower Zero Air Consumption Adsorption Dryers are used when the compressed air application requires a pressure dew point below 0°. The regenerative desiccant dryers consist of two pressure vessels. Both vessels are filled with desiccant. One vessel is removing moisture from the compressed air.

Wet air passes directly through the desiccant bed which adsorbs the moisture. When this vessel is saturated with moisture the valves will switch and lead the air to the other standby vessel. During adsorption in the other vessel, the first vessel will be regenerated. It's a cyclic process.

The desiccant medium has a finite capacity for adsorbing moisture before it must be dried out, or regenerated. To do this, the tower containing saturated desiccant medium is depressurized and the accumulated water is driven off.

How this happens depends on the type of dryer.

•Heatless dryers use only compressed air as a purge

•Blower purge dryers use a combination of air from an external blower, heat, and minimal compressed air

•Blower zero purge dryers use a combination of air from an external blower, heat, and zero compressed air

•Heat of compression dryers use the heat of the compression

•Heated purge dryers use heat and small amount of compressed air

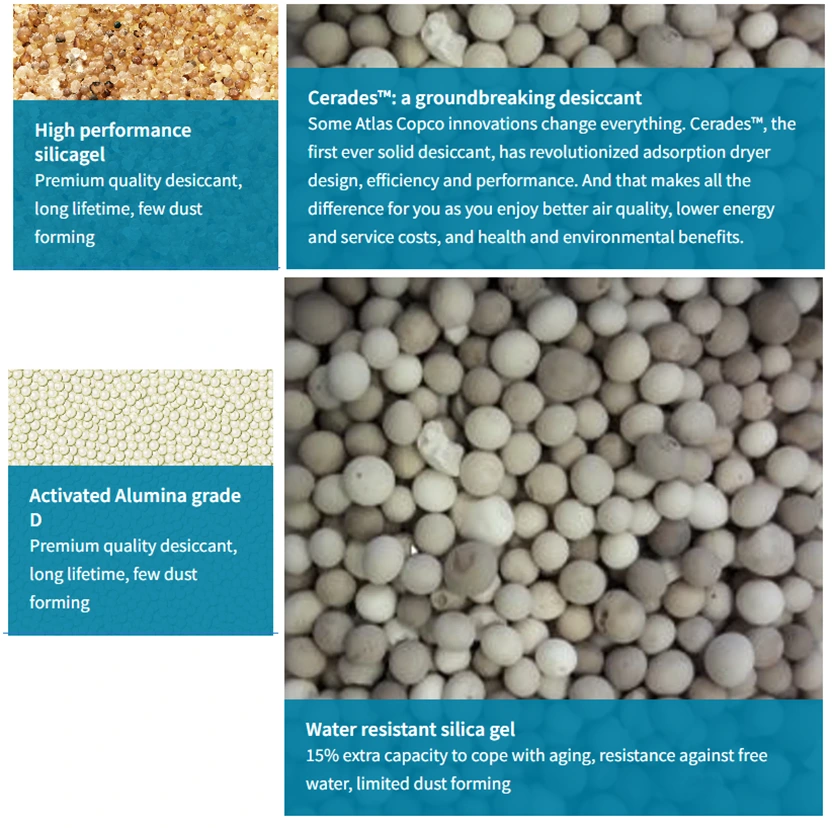

Types of desiccants

Depending on the technology and dew point requirement, there is always the best choice of desiccant, sometimes a combination of multiple layers of desiccants used in our designs. In this way, we will ensure required PDP levels and maximized lifetime for desiccant.

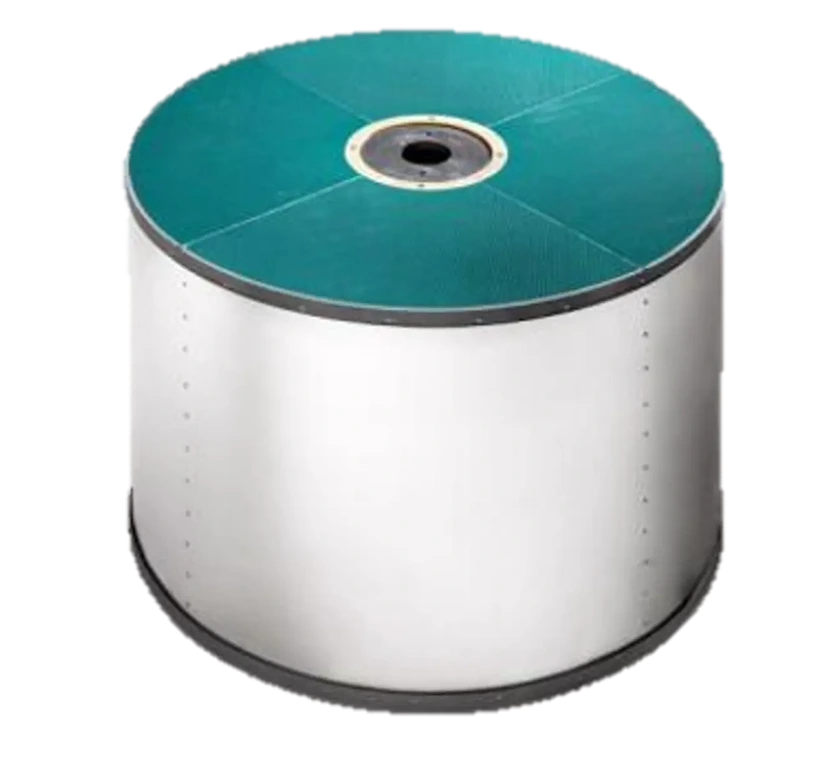

Rotary drum dryer working principle

The rotary drum dryer also uses adsorption technology. The desiccant does not come in granular form. Instead, it is bonded with a binding material in a honeycomb structure. The main advantages are:

•No erosion of desiccant beads

•No escape of beads

This unique technology does not require any additional energy, as it is using the heat of compression. The rotating drum is divided into sections. In general 3/4 of the drum is used for adsorption, while 1/4 is used for regeneration. It's a continuous process as the drum rotates and therefore doesn't require any switching valves.

structured desiccant rotary drum dryer

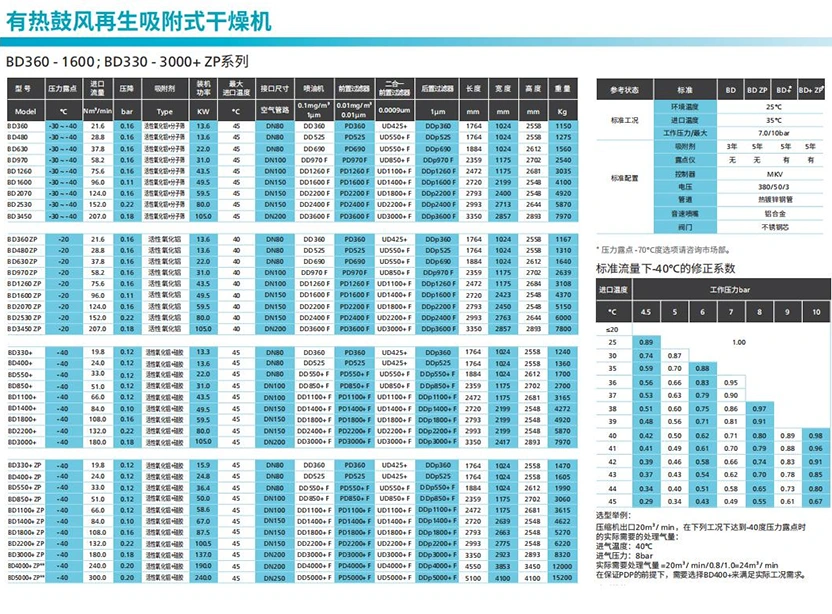

Blower-Air Hot Regeneration Adsorption Dryer (BD, BD ZP, BD+, BD+ ZP)

Blower Zero Air Consumption Adsorption Dryer uses a desiccant to adsorb moisture from compressed air. The machine consists of two identical towers. They switch between each other after a cycle.

When one tower is in adsorption mode, the other tower is in regeneration mode. The regeneration of the adsorbent consumes heat from the electric heater and a small amount of finished compressed air. For the model with zero air consumption, the regenerated air can be recycled.

When dew point control is adopted, the switching time is further extended to save energy to the greatest extent.

Depending on the pressure dew point, desiccants can be made of alumina, silica gel or molecular sieve materials. The minimum pressure dew point can reach -70℃.

■ The Blower Zero Air Consumption Adsorption Dryer is particularly suitable for medium to large-volume air applications.

■ Excellent energy efficiency comes from a low pressure drop design, high-efficiency adsorbent materials, and intelligent control of the blower and electric heater.

■ High-end hardware configuration ensures stable and reliable performance. Minimal maintenance required.

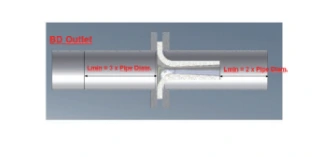

■ The inlet and outlet pipes can be freely reversed 180° for connection.

■ The sonic nozzle is installed at the rear of the dryer to prevent overflow. When multiple dryers are used in parallel, the air volume is evenly distributed to each dryer.

Hot air regeneration adsorption dryer

BD360-1600; BD330-3000+ZP series