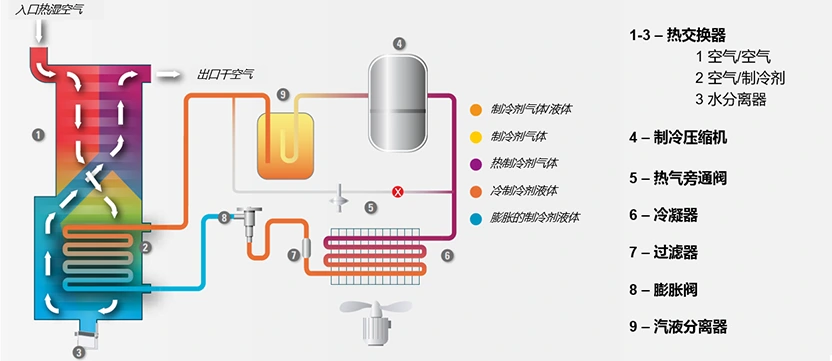

The Atlas Copco F-type refrigerated air dryer uses a three-in-one heat exchanger that combines air/air, air/refrigerant, and water separators. This effectively removes the liquid water separated after cooling and pre-cools the compressed air, improving heat exchange efficiency. We are a professional Post-processing Equipment manufacturer and supplier in China. Welcome to consult and purchase.

The Atlas Copco F-type refrigerated air dryer uses a three-in-one heat exchanger that combines air/air, air/refrigerant, and water separators. This effectively removes the liquid water separated after cooling and pre-cools the compressed air, improving heat exchange efficiency.

Compressed air serves many different industrial fields. It needs to be clean and dry everywhere, at every moment. Raw compressed air has solid, liquid and gaseous impurities. These substances can harm your air system and finished products. Moisture is a key part of untreated air. It can cause issues like pipeline rust, early wear of pneumatic tools and product spoilage.

1. Avoiding the Hazards of Moisture

When the air around us is compressed, the concentration of water vapor and particles in it increases sharply. For instance, the indoor ambient air is compressed to 7bar (e)/100 psig, increasing the vapor content or humidity by approximately 8 times, and then cooled to form liquid water. The amount of water depends on the specific application. Compressed air can actually contain three forms of water: liquid water, water mist (fog) and vapor (gas). Therefore, it is extremely crucial to effectively remove moisture from compressed air.

2. Moisture in the Air Can Cause

− Corrosion of compressed air pipes.

− Damage and malfunction of pneumatic equipment.

− Pipe corrosion, leading to compressed air leaks.

- Poor coating quality leads to a deterioration in the electrostatic spraying process.

- Decreased final product quality.

3. Dehydration Principle of Refrigerated Dryers

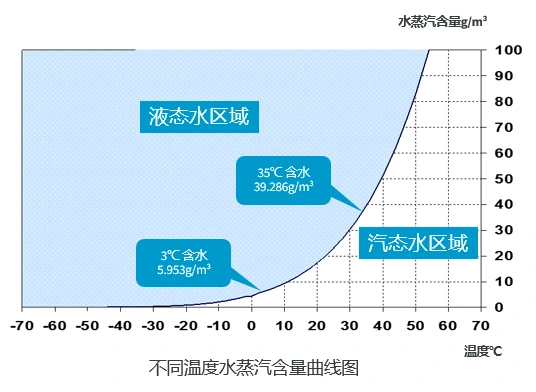

The figure shows air holds different amounts of water vapor at different temperatures. Air cools down, and its water vapor level goes down too. The curve has points that mark saturated water vapor levels. The temperature for each of these points is the dew point. A lower dew point means less water vapor in the compressed air. Refrigerated Air Dryers use this physical rule. They let compressed air swap heat with refrigerant. This action brings down the compressed air’s temperature. The cooled air’s water vapor turns into liquid water. This liquid gets drained out of the system.For instance, the saturated water vapor content of compressed air at 35℃ is 39.286 g/m³. After heat exchange with the refrigerant and cooling to 3℃, the saturated water vapor content is 5.953g /m³. The difference of 33.333g /m³ indicates the amount of water removed after cooling and dehydration by the freeze dryer. That is to say, after the compressed air passes through the freeze dryer, approximately 85% of the moisture is removed, ensuring that the drying of the compressed air meets the production process requirements.

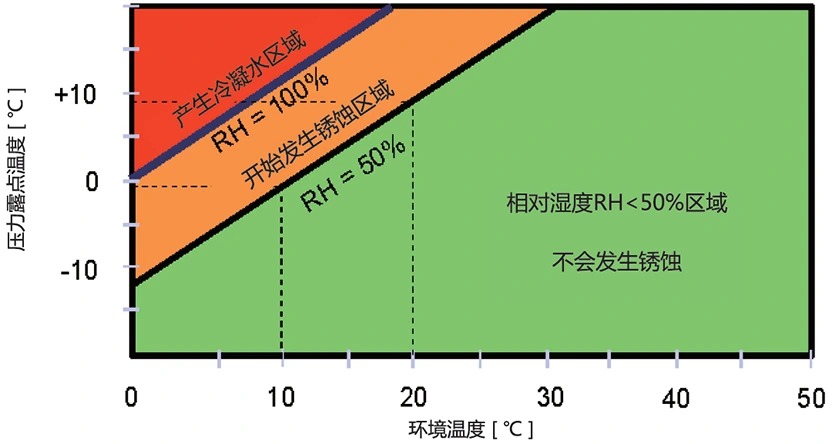

Further analysis shows that cooling compressed air only turns water vapor into liquid water. It then splits this liquid water away from the compressed air. Poor drainage lets liquid water flow back into downstream pipes with the compressed air. The desired water separation result won’t be reached this way. Condensed compressed air has 100% relative humidity. The air’s temperature needs to rise to lower this humidity. Without that temperature boost, water vapor in the compressed air will still eat away at pipes and air-powered tools. Compressed air’s relative humidity drops when heated. Cooled, condensed and dewatered compressed air needs a temperature increase. This brings humidity down to under 50%.

The Atlas Copco F-type refrigerated air dryer employs a three-in-one heat exchanger combining air/air, air/refrigerant, and water separators. This effectively removes liquid water separated after cooling and pre-cools the compressed air, improving heat exchange efficiency. Simultaneously, it heats the dehydrated compressed air to a temperature 10°C lower than the inlet temperature, ensuring the relative humidity of the compressed air after treatment is below 50%, preventing corrosion and achieving the true dehydration effect of a refrigerated air dryer.

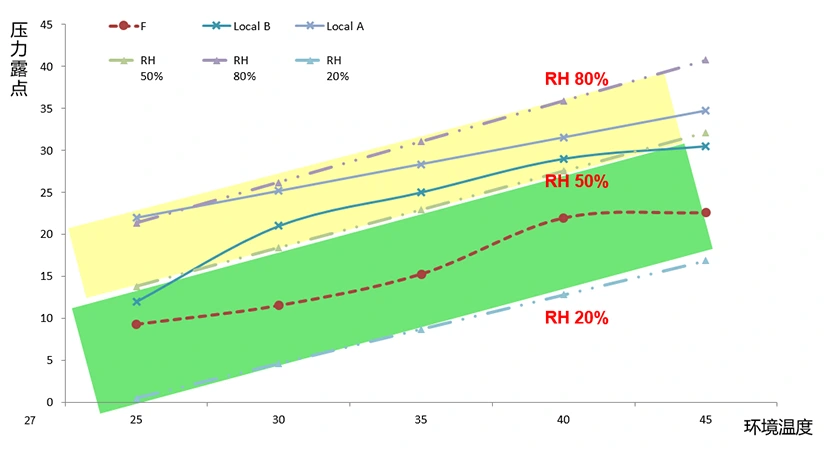

As shown in the measured data below, with a compressed air inlet pressure of 7 Bar, an inlet temperature of 35°C, a pressure dew point of 7°C, and a final exhaust temperature of 25°C, the relative humidity of the air is 30%, effectively preventing corrosion of pipelines and air-using equipment.

F6-400 (F6, F11, F25, F35, F55, F75, F95, F120, F140, F180, F230, F285, F335, and F400)

Standard Supply Scope: The F6-400 is an air-cooled refrigerated compressed air dryer. The dryer unit includes all internal piping, fittings, and electrical systems. It comprises a direct-drive, high-performance refrigeration compressor, a fully enclosed air-cooled motor, and lubrication, cooling, and conditioning systems.

The dryer is housed in a soundproof enclosure. The front panel features a computer control module with a start/stop button and a dew point display.

The F6-400 is designed for continuous operation under the most extreme conditions. All rotating parts are fully enclosed, preventing contamination and ensuring long-term, reliable operation. The dryer's cooling system is specifically designed to operate well in ambient temperatures up to 45°C/113°F.

Component Description: